A tenter frame tensions and stretches the substrate over the required width.

The substrate is fed into the first dryer under tension after the initial coating. The applied tension prevents the coated goods from contracting at temperatures of around 125 to 165°C.

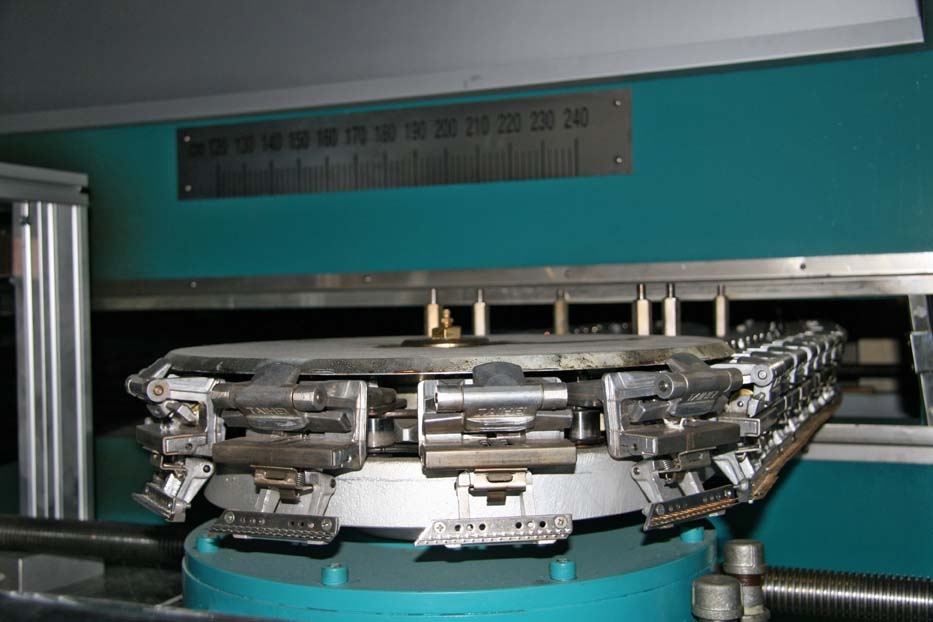

The most important parts of a tenter frame are the needle/peg devices that keep the products level on both sides. The tenter frames that run through the entire dryer are width-adjustable and can be positioned horizontally or vertically.