Laser Drying Technology Takes Leap Forward: IDEEL Project Demonstrates Scalability for Efficient Battery Cell Production

More Economic and Climate-Friendly Anode and Cathode Drying

Electrode drying in the roll-to-roll process (R2R) has so far been one of the most cost- and CO2- intensive manufacturing steps in the production of lithium-ion batteries. A laser-based R2R drying process developed as part of the IDEEL research cooperation could change this in the future. It combines conventional, oven-based convection drying with laser drying using high-power diode lasers and reduces the drying time by more than 60 percent while maintaining the same quality of results.

Mülheim-Kärlich, March 19, 2025 – In the industrial production of lithium-ion batteries, electrode drying was previously one of the most critical sub-processes. The high energy and time consumption, as well as the significant space requirements made the drying of the active paste (slurry) applied to a current conductor foil in the roll-to-roll process (R2R) one of the most cost- and CO2-intensive manufacturing steps in the entire battery production process. Against this background, the IDEEL (Implementation of Laser Drying Processes for Economical & Ecological Lithium-Ion Battery Production) research project, which was completed on December 31, 2024 after three years of research, explored alternative drying processes using highly efficient large- area laser irradiation. The project was supported by the German Federal Ministry of Education and Research as part of the Battery 2020 funding program and was coordinated by Laserline GmbH. Additional project partners included the Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University, Coatema Coating Machinery GmbH, Optris GmbH, the Fraunhofer Institute for Laser Technology (ILT), the Münster Electrochemical Energy Technology (MEET) Battery Research Center at the University of Münster and the Fraunhofer Research Institution for Battery Cell Production (FFB).

Development and Optimization of Laser Drying as a Project Focus

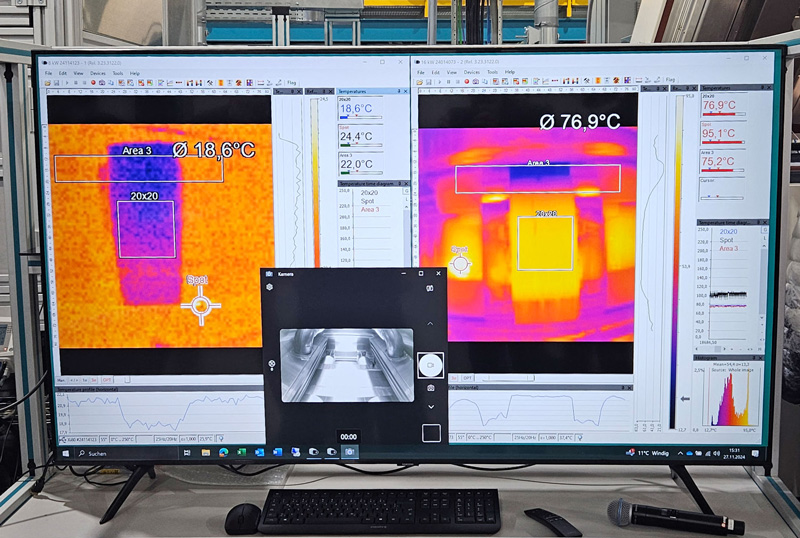

The initial focus of the IDEEL research cooperation was the development and gradual optimization of a suitable laser drying process. To this end, materials for anode and cathode coatings were specifically validated for laser application, and aqueous formulations based on graphite, lithium iron phosphate and silicon graphite were successfully tested (PEM at RWTH Aachen University, MEET Battery Research Center at the University of Münster). A highly efficient diode laser system with a wall plug efficiency of over 50 percent and new processing head with coaxial thermographic coupling and a rectangular laser spot over 0.5 meters wide (Laserline) served as the heat source. To enable contactless, automated process monitoring and control, a highly integrated thermographic camera with industry PC-compatible data output was developed. This system ensures consistent target temperature maintenance even with varying web speeds and coating thicknesses (Optris, Laserline, Fraunhofer ILT). Based on these system components, a modular laser drying unit was developed as a demonstrator, featuring a specialized air management concept and custom dual-chamber wide-slot nozzles for the fast and reliable application of water- based battery pastes (Coatema). Within this demonstrator, the laser-based R2R drying process was upscaled to industrially relevant feed rates while simultaneously determining and validating the optimal process configuration (Fraunhofer ILT, FFB).

Hybrid Process Enables Industrial Scaling

Since drying requires both heating and mass transport via air extraction, the most technically and economically promising approach was to implement a hybrid configuration with hot air and laser modules. In this R2R process configuration, laser drying enables rapid heating and pre-drying of the slurry, while a downstream convection oven prolongs temperature exposure, ensuring thorough drying of the electrode coating. This approach also allows existing facilities to benefit from the new method by retrofitting laser modules, combining technical optimization with the sustainable use of capital goods. As part of this effort, the project partners developed an innovative hybrid drying system that, for the first time, achieves a web speed of 30 meters per minute and reduces drying times by more than 60%. Additionally, the laser booster at the start of the process cuts the required oven length in half, saving valuable production space and significantly reducing the demand for energy-intensive dry rooms. The operational costs of the drying process decrease by 20 to 30% overall. Furthermore, the reduced oven operation, coupled with the ongoing utilization of a retrofitted system throughout its remaining lifecycle, results in a substantial enhancement of the overall CO2 footprint. This new approach enables more cost- effective and environmentally friendly processes, which in turn significantly enhances the economic and ecological balance of battery production.

Studies Confirm Equivalent Results with Increased Throughput

Experimental studies conducted by Fraunhofer ILT, PEM of RWTH Aachen University, MEET Battery Research Center, and FFB demonstrated that the results of hybrid drying are equivalent to those of established convection drying. Despite increased throughput rates, the quality of electrode performance remains at least equivalent in terms of adhesion, residual moisture, electrical conductivity, and electrochemical properties. The industrial relevance of the newly developed process is thus fully validated. The process insights developed within the IDEEL project will consequently be incorporated into the work of FFB, which is set to become a development center for modern battery cell production in Germany and its European partners.

About Coatema Coating Machinery GmbH:

Coatema Coating Machinery GmbH is a leading provider of advanced coating and printing solutions for a range of industries, including deep tech markets such as batteries, solar, prepregs, medical, fuel cells, green hydrogen, and printed electronics. We are specialized in designing and manufacturing Sheet-to-Sheet and Roll-to-Roll equipment for the coating, printing, and laminating sectors, with a focus on upscaling technologies from Lab2Fab to meet the needs of its customers. With over 10 pilot lines in Europe's largest R&D center and a team with over 12 public funded projects, Coatema offers a wide range of services for process and product development, in addition to its core equipment business, to support customers in achieving their goals.

More information: https://www.coatema.com

Here you can download the press release as PDF: Press release IDEEL

|

Contact Laserline: Laserline GmbH |

Contact agency: Riba:BusinessTalk GmbH# |

Marketing Contact:

Tanja Simone, Marketing Manager

Phone +49 (0) 21 33 / 97 84 – 121

This email address is being protected from spambots. You need JavaScript enabled to view it. | www.coatema.com