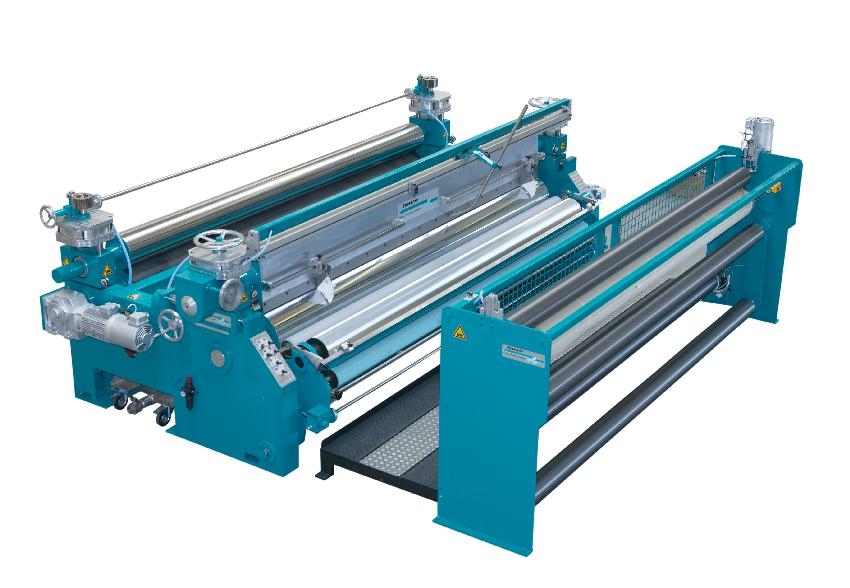

Production machinery

Discover Coatema's production coating and laminating machines, the culmination of our lab2fab process. With tailored production plants featuring over 40 coating and laminating systems, optimized drying solutions, and advanced process technology, we deliver speed, efficiency and quality control.

Our production plants are ideal for high-throughput requirements, offering flexibility in design and customization. Working closely with customers, our design and engineering teams ensure solutions meet the most demanding requirements for production, efficiency and product quality.

With tried-and-tested standard solutions and customer-driven development, Coatema brings state-of-the-art tools to high-throughput markets. Benefit from our more than 40 years of experience, extensive expertise, and continuous improvement philosophy, all delivered from one source.

Explore our small and large format testing solutions at the Coatema R&D centre.

If you have a special requirement, contact us at This email address is being protected from spambots. You need JavaScript enabled to view it.. Let us help you find the perfect machine for your needs.