Prepreg and composite materials

Coatema offers innovative plant concepts for the coating of composite materials with duroplastic and thermoplastic adhesives. Here, Coatema develops extremely successful high-temperature applications in the field of thermoplastic applications.

Today, the use of coated products for prepregs is growing rapidly. This increasing demand has motivated Coatema to develop new, highly innovative plant concepts for impregnation and coating. The unique designs of the powerful coating technologies and the effective processing of the fibre materials of the prepreg products involve a range of mechanical and technical challenges and attest to the plant design innovation and engineering know-how of Coatema.

Prepregs are pre-impregnated fibres with tailor-made properties. They bring benefits such as high strength, high tension force, low material densities, corrosion resistance, high vibration resistance, low heat elongation, low weight, really low material fatigue, easy on-site installation and low maintenance costs.

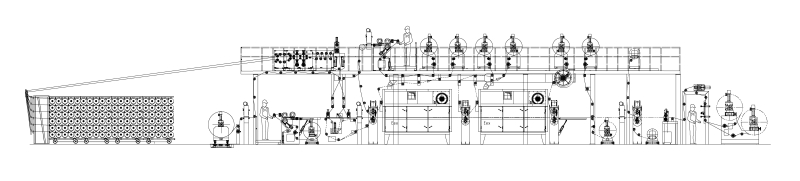

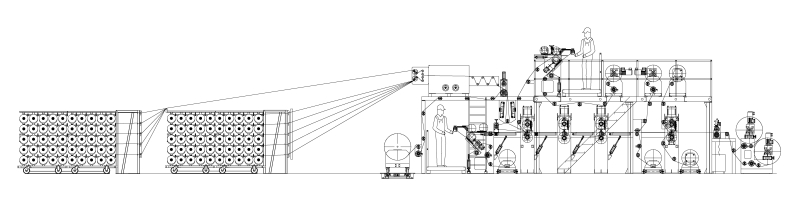

Coatema has successfully supported our customers in light of the increasing demand for fibre-reinforced plastics with highly innovative machine concepts for the manufacture of prepreg products. Our flexible, multifunctional coating plants enable the ideal processing of fibre materials/substrates and the production of diverse prepreg products from rovings, textiles and multiaxial structures.

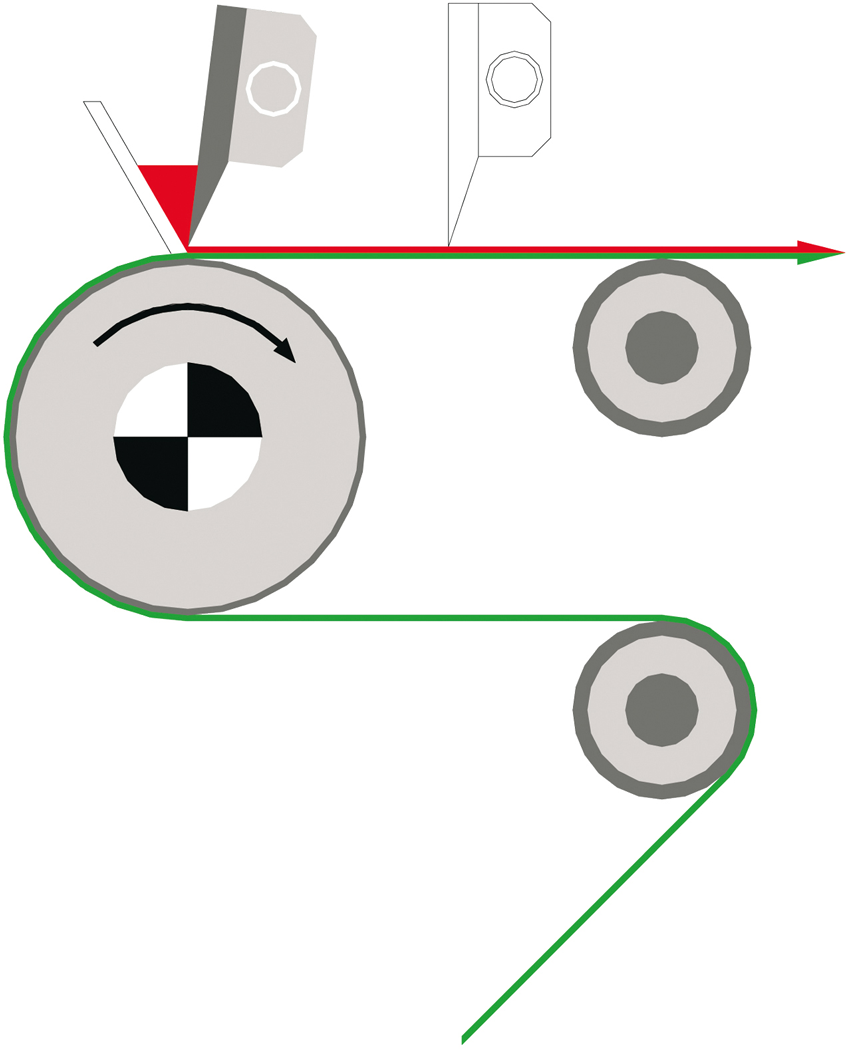

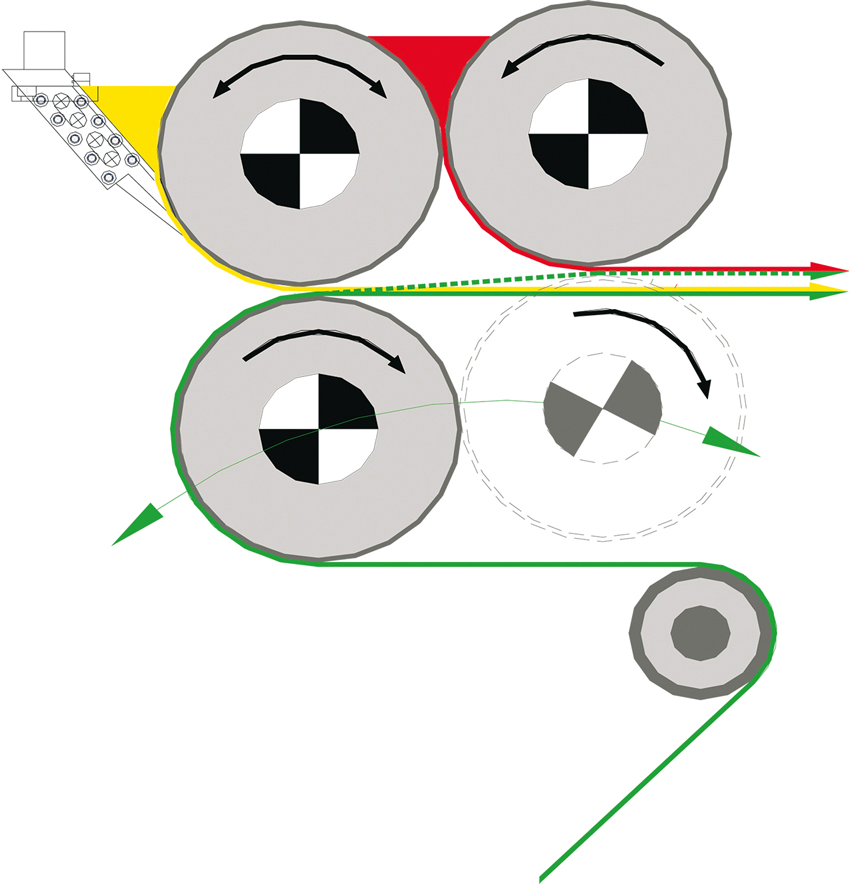

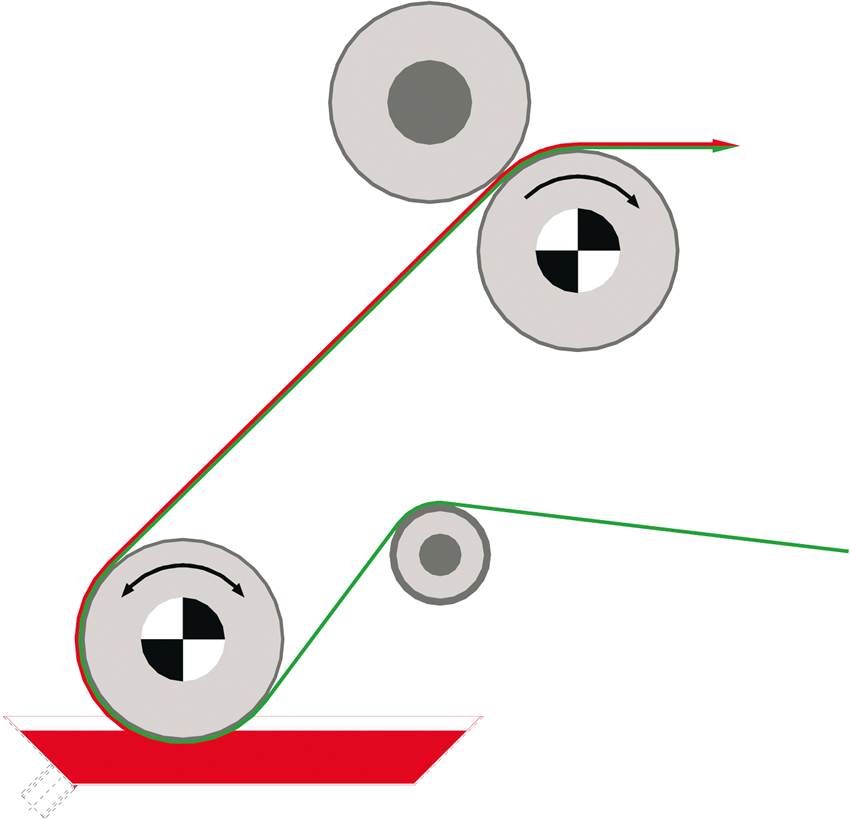

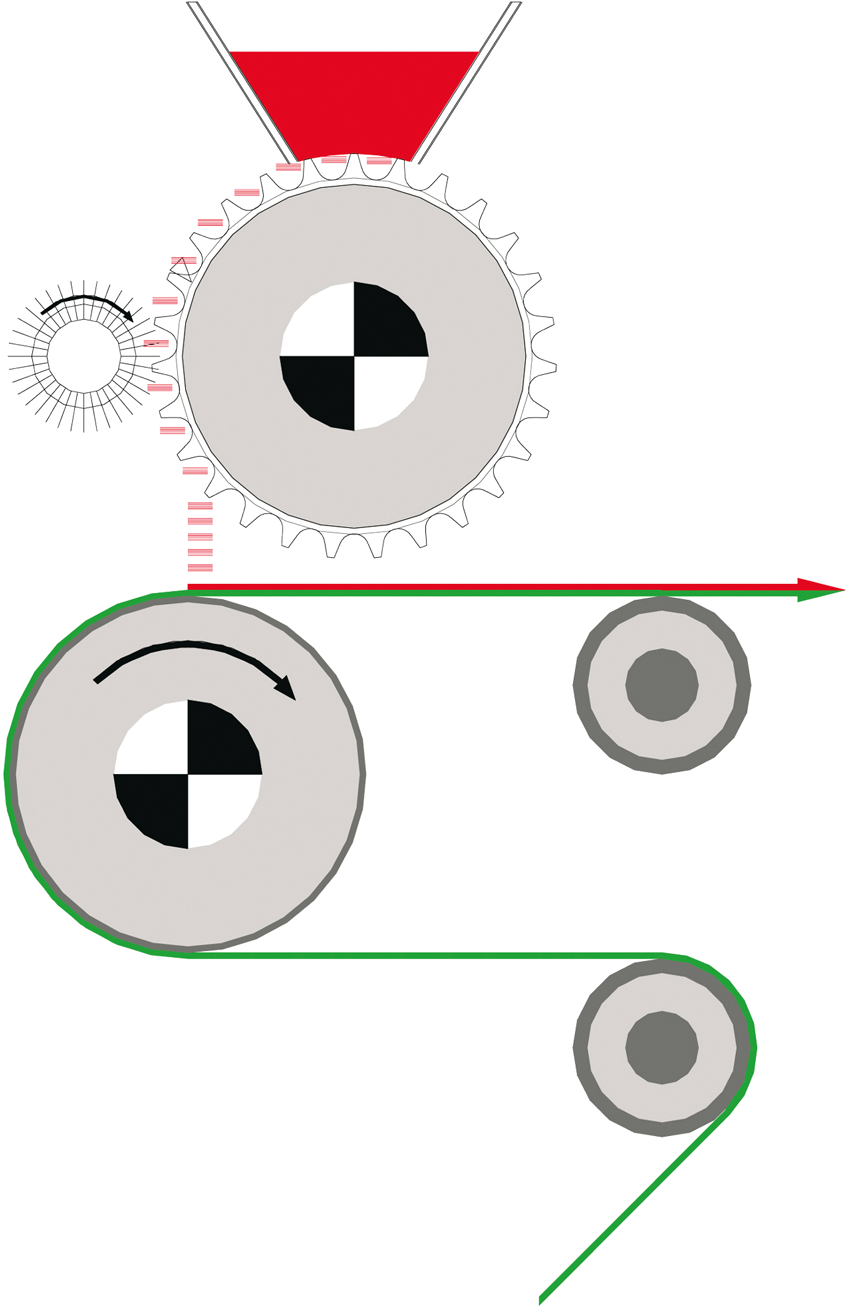

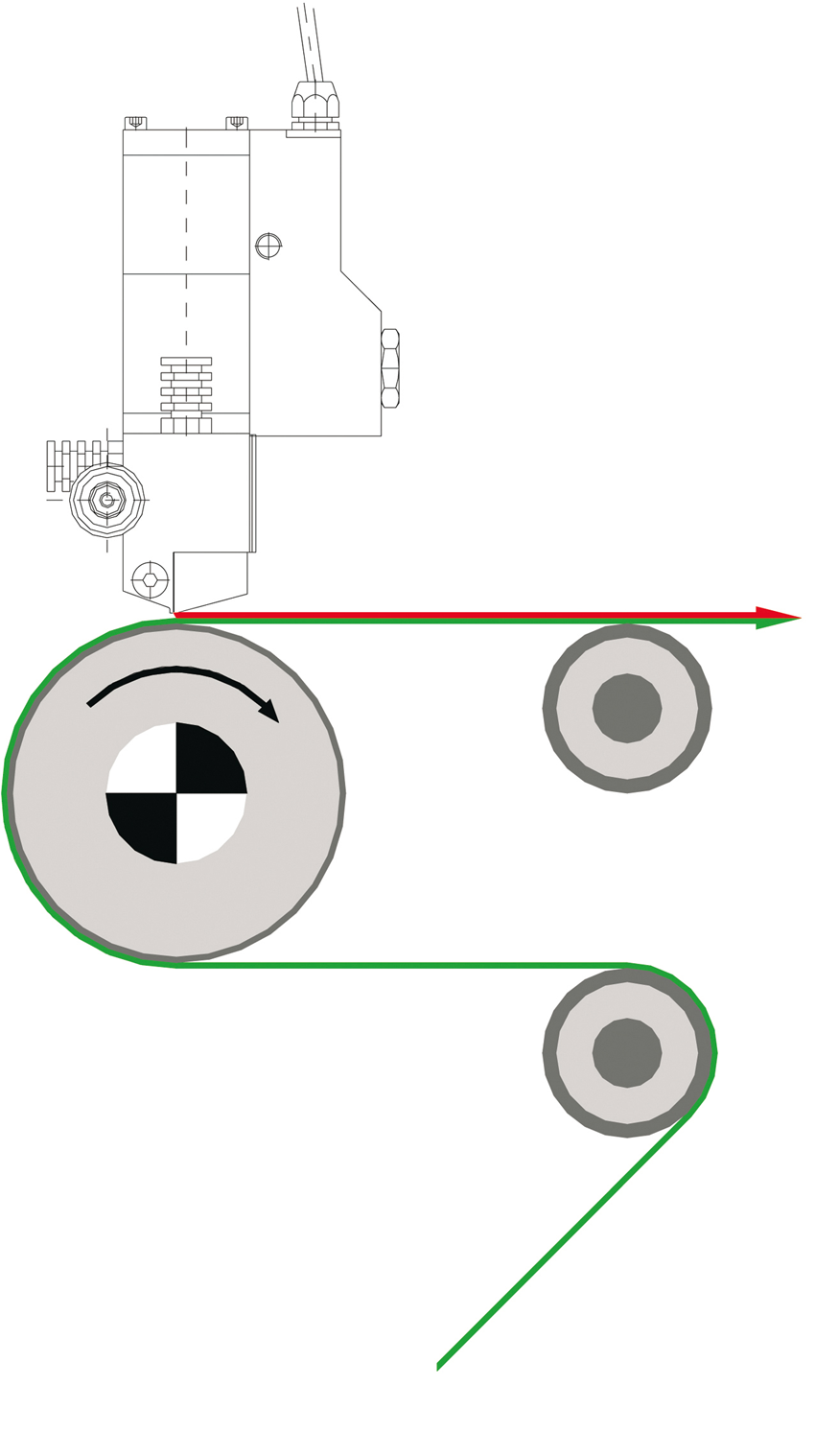

As a rule, the necessary machine concept here includes the application of epoxy resin or phenolic resin to diverse types of substrate. Depending on the substrate structure, processing takes place as rovings with a thread frame or as textile sheeting material using roll unwinding. The following coating systems can be used here: Doctor blade, powder scattering method, slot dies, hotmelt slot dies and impregnation. These are available as modular coating heads that can be quickly changed, giving a high level of flexibility.

To receive detailed quotations, please contact our project planning team at This email address is being protected from spambots. You need JavaScript enabled to view it. or your local Coatema agent.

Scale-up process

Coatema offers plants in the basic research field ranging from laboratory coaters to pilot plants and production machines for the production of semi-finished products for fibre-reinforced plastics. Coatema can process diverse base products with our coating plants. Generally, these are based on carbon, glass, Kevlar® and synthetic fibres.

The substrates to be processed take many different forms such as rovings, woven fabric and uni/bi/multidirectional fibre structures or even products that have multiple orientations in accordance with the required direction of force in the final application. For the various prepreg products, we offer plants with working widths ranging from DIN A4 to 2,000 mm in the R2R field.