Questions and answers

1. What are the normal lab times?

Testing times: 9:00 a.m. to 4:00 p.m.

If you know in advance that you'll need several hours longer, these extra hours must be paid for at the rate stated in the laboratory terms and conditions.

2. How much material (substrate and coating fluid) do we need?

Substrates

Ideally, the length of the substrate should be slightly larger than the following:

Length to be coated + 2 x machine length

It is then possible to fill the machine with the original material and to leave it filled after the test (as a threading aid for later tests).

Core: 3 inch; adapter for 6 inch cores available

Fluid

The minimum amount of fluid is calculated as follows:

Coating width x coating length x wet film thickness + dead volume (pump, die, hoses etc.)

However, these rules apply only in cases where all tests run without any complications. This is frequently not the case. More often, dies, doctor blades, Foulard basins etc. need to be cleaned and refilled unexpectedly. The amount of dead fluid volume used for pit stops like this can be much larger than the amount calculated for the ideal scenario. We therefore recommend supplying a sufficiently large quantity as a safety margin. Otherwise, you might face the unpleasant situation of having to discontinue testing due to a lack of material.

3. Can we coat a limited substrate length with leading and trailing materials?

In principle, yes. However, doing so poses certain risks:

- The leading and trailing material often does not behave in exactly the same way as the original material.

- The splicing points must be able to withstand the web tension and temperature in the dryer.

- Coating must be started accurately after the first splice and before the second splice.

- Splice points can get stuck in narrow gaps (e.g. corona).

For these reasons, we recommend that you use the original material as the leading/trailing material, too.

4. What mixers are available?

- 20l mixer with blade agitator or dispersion disk

Edge scraper

Degassing evacuation option

Stirring tank, can be heated or chilled - Laboratory DISPERMAT for containers up to around 3l

Dispersion disk or blade agitator - Laboratory agitator for containers up to around 2l, blade agitator

- Laboratory magnetic stirrer

- Flask shaker

What measurement possibilities are available?

Mechanical wet film thickness gauge

- Various scales from µg to kg (with defined sample cutter)

- Mechanical and mechanical-electronic sensing devices

- Radiometric absorption (online)

- Optical absorption (coming soon)

- Viscometer

- Scratch resistance (pencil hardness)

In addition, practically any measurement technology can be hired/rented from manufacturers for testing for more specialist tasks. Examples: Microwave residual moisture measurement, white-light interferometry

6. Can waste be disposed of by Coatema?

Generally, no.

Our basic laboratory terms and conditions stipulate that all materials must be supplied by and disposed of by customers. As a machine constructor, Coatema is not familiar with the applicable delivery conditions for the various chemicals. In special cases, Coatema can commission a disposal specialist to dispose of waste materials. This will be billed separately.

7. Can we process EEx or TOX substances?

Generally, yes.

Our machines are designed for this. However, discussions with the customer on a case-to-case basis must determine whether additional measures are required in the special R&D centre conditions (particularly for TOX substances). The customer must provide Coatema with applicable documents such as the MSDS etc.

8. Do materials have to be provided by the customer?

Yes, we cannot order materials for you.

9. Are samples required in advance for evaluation?

From case to case it may be necessary to examine samples in advance to check the feasibility or to select the coating system.

10. By when must the materials be received by us?

Ideally one week in advance or you can bring the materials with you.

11. To which address should the material be send?

Coatema Coating Machinery GmbH

Technical centre

Kira Grefkes

Roseller Strasse 4

41539 Dormagen

12. What machines are available in the R&D centre?

Machinery and equipment R+D centre

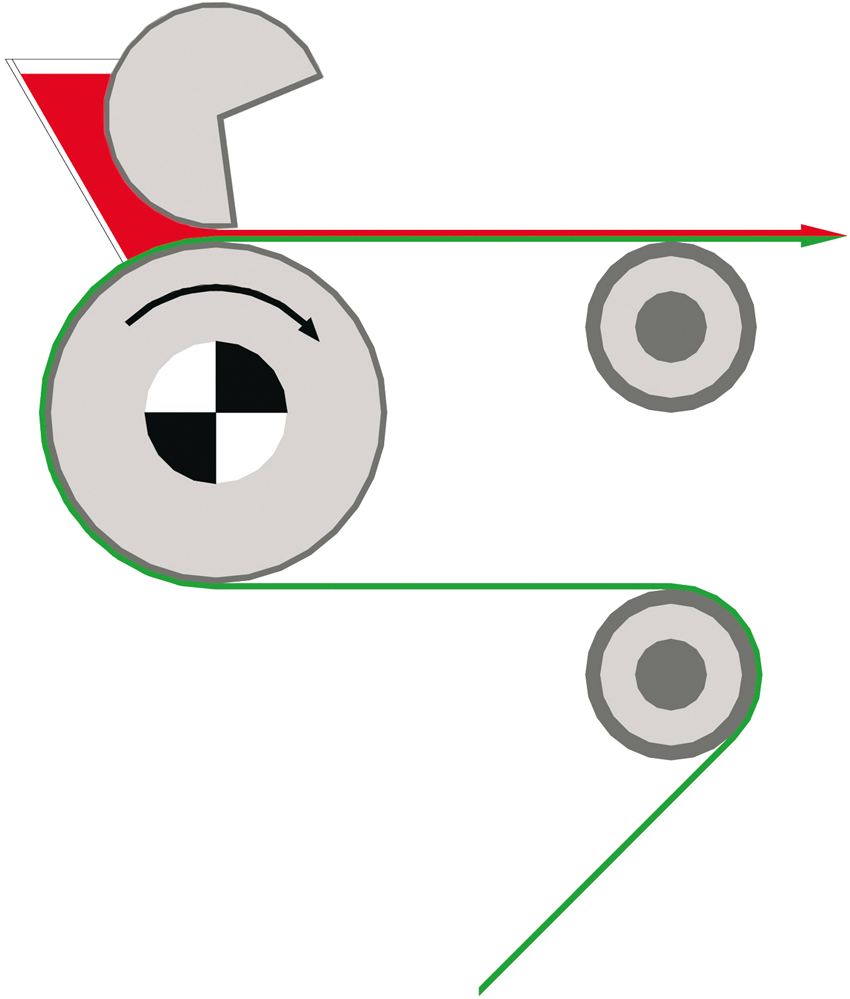

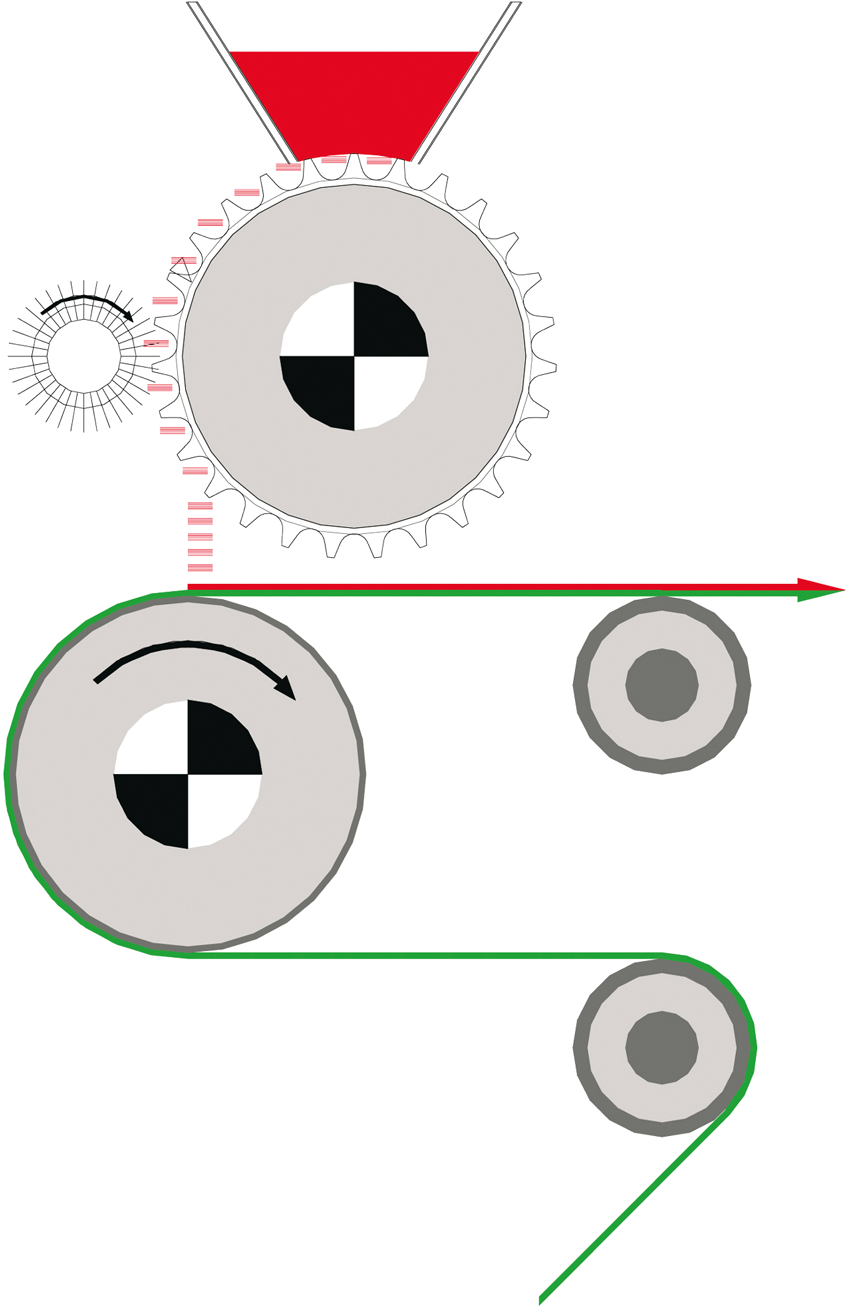

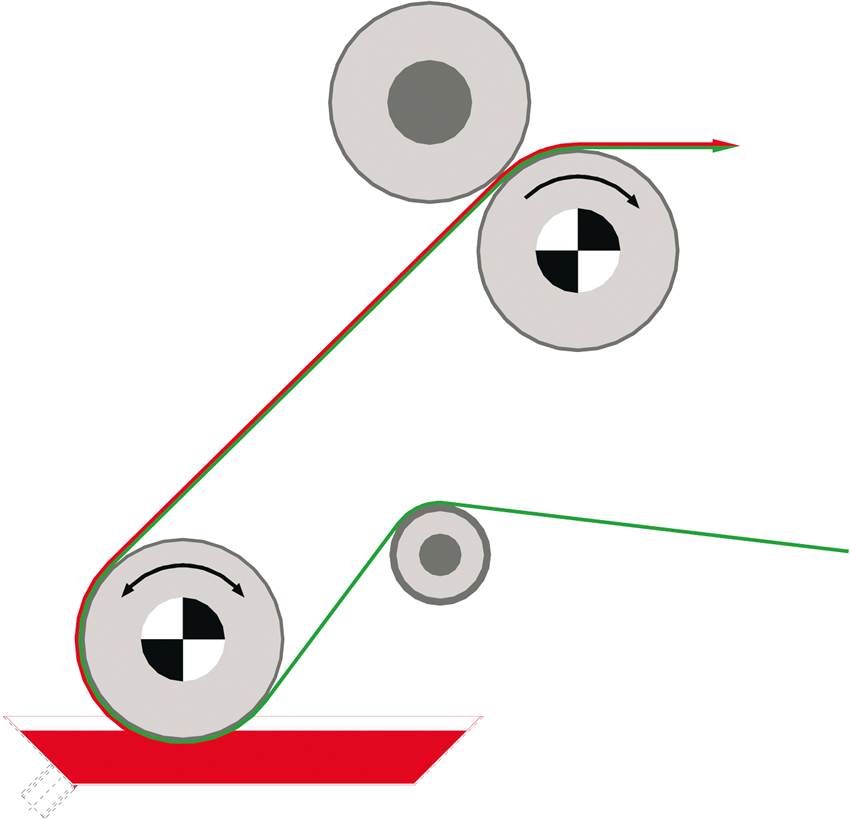

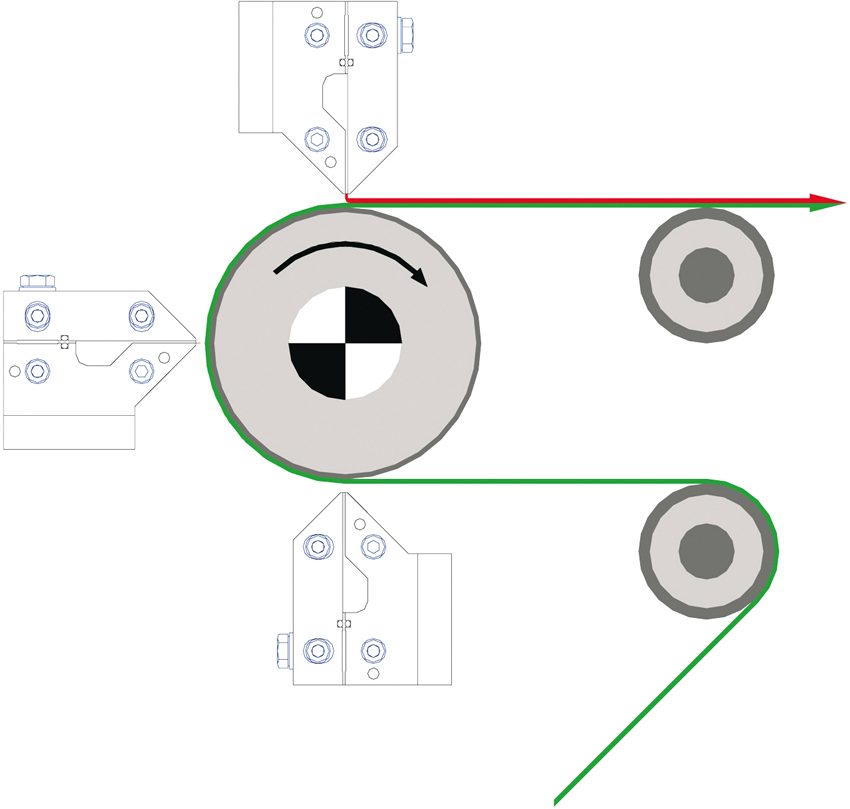

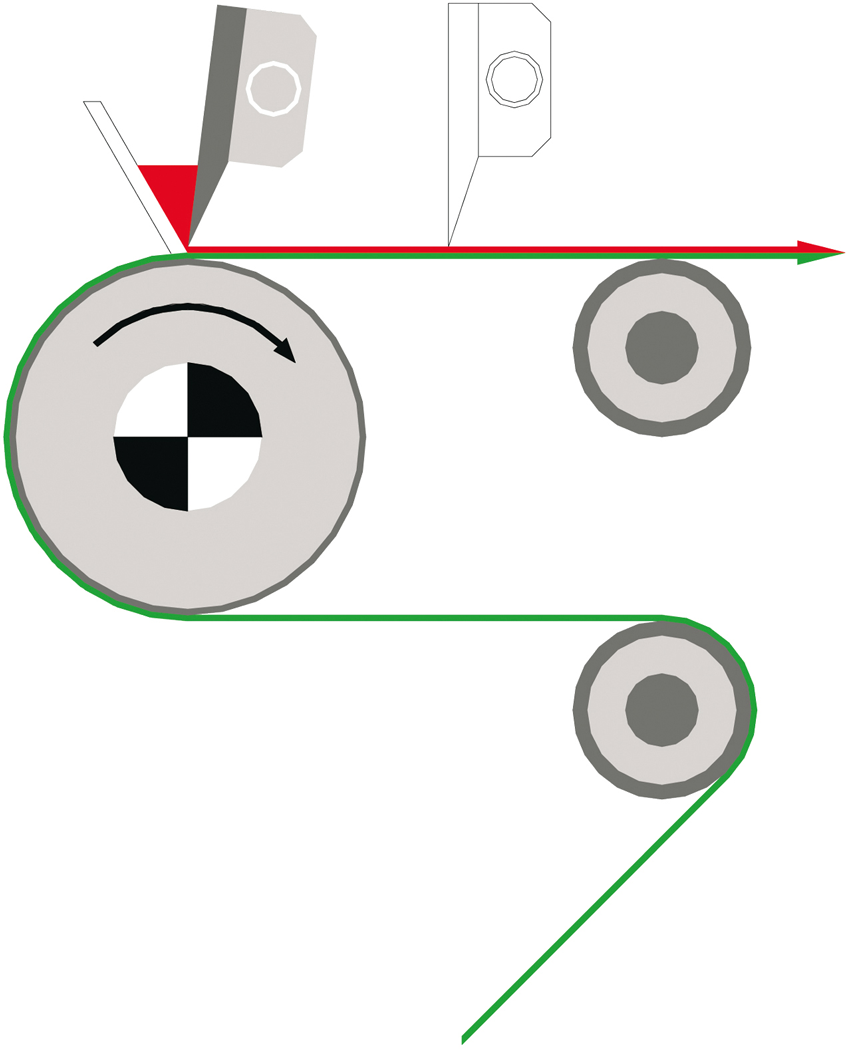

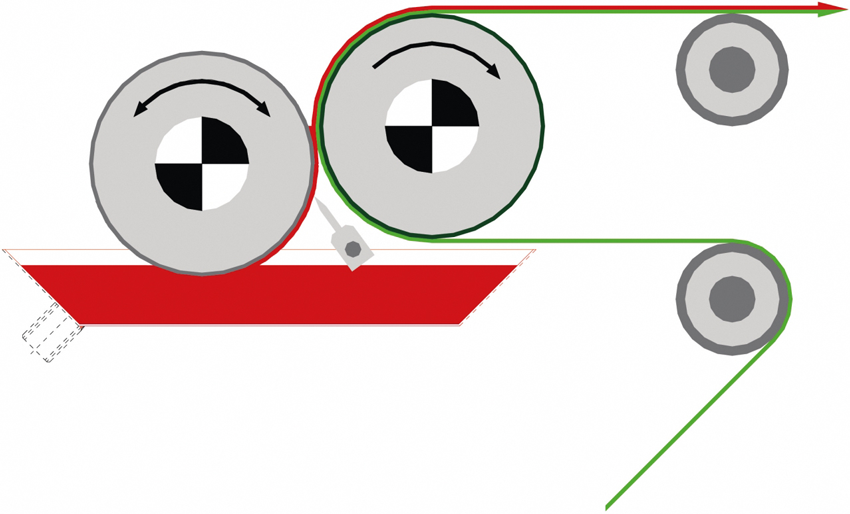

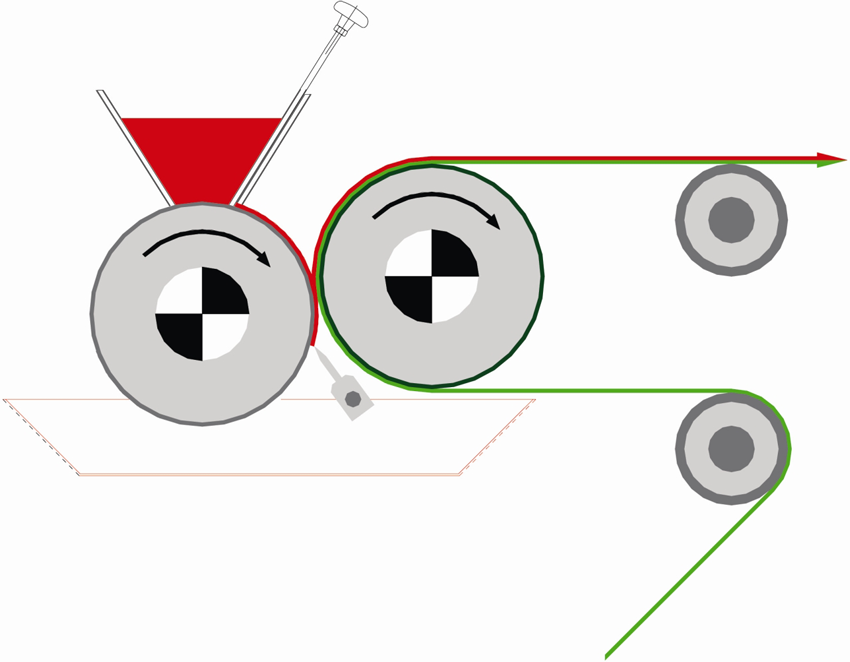

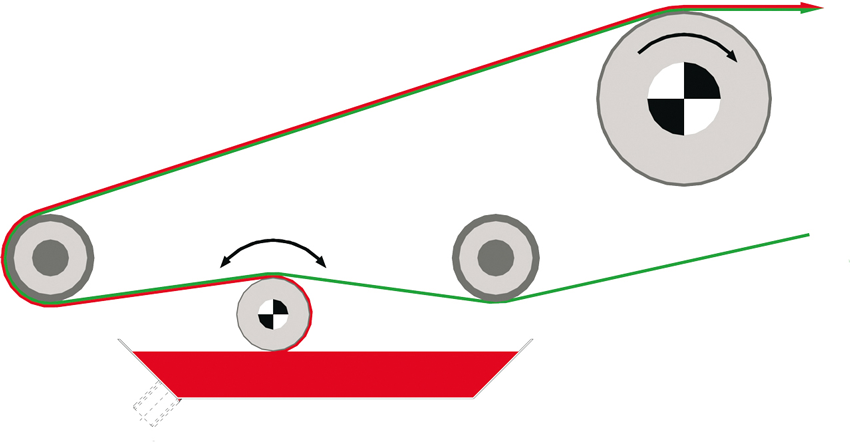

13. What coating systems are available?

Availability depends on the machine.

Machinery and equipment R+D centre

|

|

|

| Slot die | Doctor blade | 2-roller system |

|

|

|

| Rotary screen printing | Gravur printing system | Commabar |

|

|

|

|

| Powder scattering system | Foulard | Micro roller coating system |

|

|

||

14. Is it possible to extent the trials spontaneously?

In principle yes. Of course this depends on the R&D centre's workload.

15. Is it possible to perform trials under inert conditions?

Yes, a certain number of machines are available for this purpose.

16. What processes can be carried out?

The R&D centre can carry out tests with sheets (S2S) and roll-to-roll (R2R scale)

17. Can the machine be changed spontaneously?

In principle, yes. This depends strongly on the machine on which the change is made. Keyword: set-up time.

18. Are the trials documented by Coatema?

Yes, you will receive a documentation containing the test data and photos after the test.

19. Can videos and photos be taken at the R&D centre?

No. Only the team of the R&D centre is allowed to take photos and videos in the R&D centre. Photo and video requests for documentation will of course be considered.

20. May tests also be carried out without the customer being present?

Of course. We offer virtual trials via stream or recorded videos.

21. How many people can take part in the test?

A maximum of 5 persons can take part in the tests.