Coatema2go

![]()

#smallbutmighty

#everythingyouneed

#sizecounts

Coatema2go: Your gateway to precision coating

Coatema2go is a new line of compact, versatile tabletop coaters designed to empower research and innovation. These coaters offer a plug-and-play setup for rapid project initiation and streamlined workflows, making them ideal for labs with limited space.

Key Features:

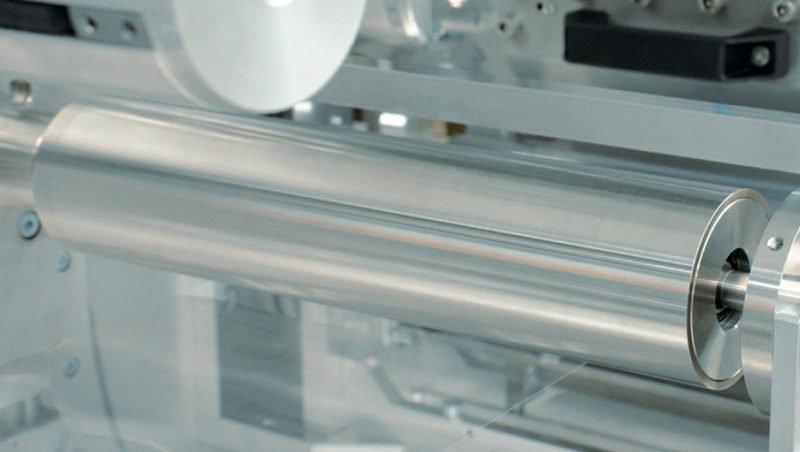

- Precision coating: Equipped with Coatema slot dies, doctor blades, and other high-quality components, Coatema2go ensures precise and consistent coating results, even at a small scale.

- Seamless scalability: Coatema2go is the entry point to Coatema‘s lab2fab philosophy, allowing users to easily transition to larger systems like the Easycoater, Smartcoater, Basecoater, and Click&Coat platform as their projects mature.

- Comprehensive R&D support: Coatema provides robust support through its extensive R&D center, specialized engineers, slot die masterclasses, international coating conferences, and simulation services.

- Proven industry leadership: With over 40 years of experience in coating, printing, and laminating, Coatema has a global reputation for reliability, technical excellence, and customer-centric solutions.

Coatema2go: Precision coating, perfectly scaled

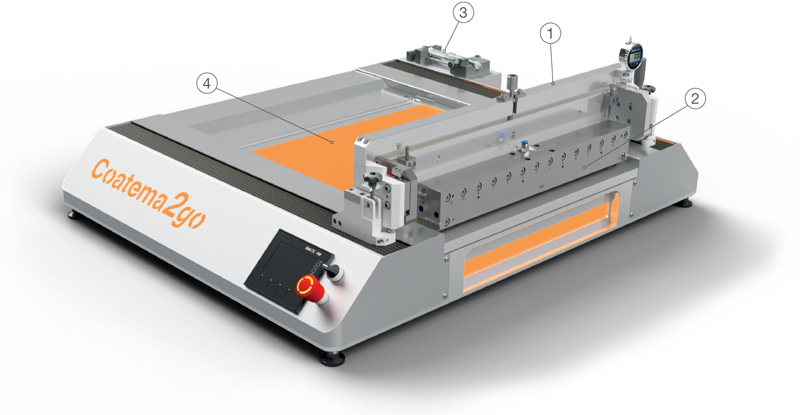

#smallbutmighty: This compact tabletop system features a servo motor driven application station with an integrated piston pump. It‘s ideal for labs with limited space and offers a plug-and-play setup for quick experimentation and proof-of-concept work. Choose from different sizes of slot dies, doctor blades, and comma bars to achieve precise coating results on a variety of substrates. The A4 vacuum table and control unit with display provide everything you need for efficient and accurate coating.Coatema2go products

#smallbutmighty

Layout feature:

1 Application system

2 Slot die

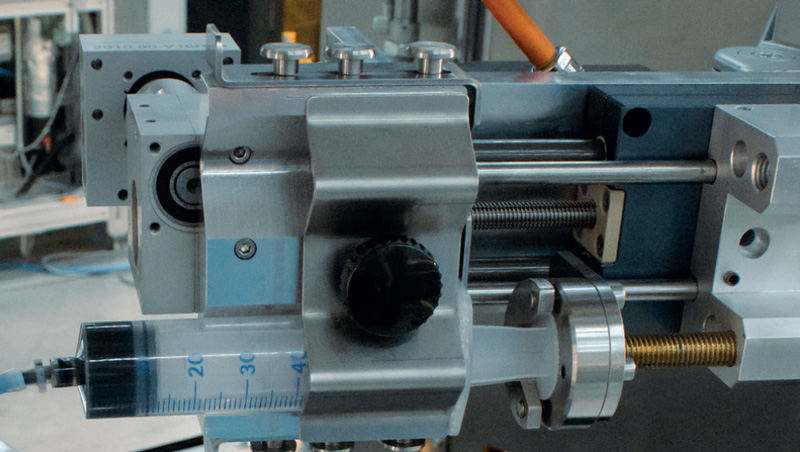

3 Piston pump

4 Vacuum table

Technical data:

650 x 647 x 420 mm (l w h)

#everythingyouneed

Layout feature:

1 Application system

2 Slot die

3 Piston pump

4 Vacuum table

5 Dryer

Technical data:

1050 x 647 x 420 mm (l w h)

#sizecounts

Layout feature:

1 Application system

2 Slot die

3 Piston pump

4 Vacuum table

Technical data:

800 x 1066 x 370 mm (l w h)

Key features

![]() Compact & versatile tabletop design: Ideal for labs with limited space, Coatema2go offers a plug-and-play setup for rapid project initiation and streamlined workflows. This allows for quick experimentation and proof-of-concept work without requiring a large factory floor.

Compact & versatile tabletop design: Ideal for labs with limited space, Coatema2go offers a plug-and-play setup for rapid project initiation and streamlined workflows. This allows for quick experimentation and proof-of-concept work without requiring a large factory floor.

![]() Precision coating with Coatema technology: Equipped with Coatema slot dies, doctor blades, and other high-quality components, Coatema2go ensures precise and consistent coating results, even at a small scale. This translates to high-quality samples and reliable data.

Precision coating with Coatema technology: Equipped with Coatema slot dies, doctor blades, and other high-quality components, Coatema2go ensures precise and consistent coating results, even at a small scale. This translates to high-quality samples and reliable data.

![]() Seamless scalability from Lab to Fab (lab2fab): Coatema2go is designed as the entry point to Coatema‘s lab2fab philosophy. Users can easily transition from the tabletop coaters to larger systems like the Easycoater, Smartcoater, Basecoater and Click&Coat platform as their projects mature. This protects initial investment and facilitates smooth scale-up.

Seamless scalability from Lab to Fab (lab2fab): Coatema2go is designed as the entry point to Coatema‘s lab2fab philosophy. Users can easily transition from the tabletop coaters to larger systems like the Easycoater, Smartcoater, Basecoater and Click&Coat platform as their projects mature. This protects initial investment and facilitates smooth scale-up.

![]() Flexible process integration & advanced technologies: Coatema lab, pilot & production lines supports a wide range of coating methods and substrates. It also offers the option to integrate advanced processes like LIFT, Inkjet, spatial ALD R2R, and laser drying, enabling cutting-edge research and development. This allows users to experiment with the latest techniques.

Flexible process integration & advanced technologies: Coatema lab, pilot & production lines supports a wide range of coating methods and substrates. It also offers the option to integrate advanced processes like LIFT, Inkjet, spatial ALD R2R, and laser drying, enabling cutting-edge research and development. This allows users to experiment with the latest techniques.

![]() Comprehensive R&D support & expertise: Coatema provides robust support through its extensive R&D centre (with 8 pilot lines), specialized engineers, slot die masterclasses, international coating conferences, and simulation services. This gives users access to unparalleled expertise and resources.

Comprehensive R&D support & expertise: Coatema provides robust support through its extensive R&D centre (with 8 pilot lines), specialized engineers, slot die masterclasses, international coating conferences, and simulation services. This gives users access to unparalleled expertise and resources.

![]() Proven industry leadership & reliability: With over 40 years of experience in coating, printing, and laminating, Coatema has a global reputation for reliability, technical excellence, and customer- centric solutions. Coatema2go benefits from this legacy, providing users with a trusted and dependable platform.

Proven industry leadership & reliability: With over 40 years of experience in coating, printing, and laminating, Coatema has a global reputation for reliability, technical excellence, and customer- centric solutions. Coatema2go benefits from this legacy, providing users with a trusted and dependable platform.

Markets

![]() Batteries: Coatema‘s expertise in battery coating technologies, from electrode materials to separators, ensures precise and scalable solutions. Coatema2go enables rapid prototyping and optimization of battery components, accelerating advancements in energy storage.

Batteries: Coatema‘s expertise in battery coating technologies, from electrode materials to separators, ensures precise and scalable solutions. Coatema2go enables rapid prototyping and optimization of battery components, accelerating advancements in energy storage.

![]() Fuel Cells: With experience in fuel cell component coatings, Coatema offers proven solutions for enhanced performance and durability. Coatema2go facilitates the development and testing of new fuel cell materials and coatings, driving innovation in clean energy.

Fuel Cells: With experience in fuel cell component coatings, Coatema offers proven solutions for enhanced performance and durability. Coatema2go facilitates the development and testing of new fuel cell materials and coatings, driving innovation in clean energy.

![]() Green Hydrogen: Building on expertise in related fields, Coatema is ready to support the emerging green hydrogen market. Coatema2go systems offer a platform for developing and testing advanced coatings for electrolyzers and other critical components.

Green Hydrogen: Building on expertise in related fields, Coatema is ready to support the emerging green hydrogen market. Coatema2go systems offer a platform for developing and testing advanced coatings for electrolyzers and other critical components.

![]() 3rd Generation PV (OPV and Perovskite): Coatema‘s experience in OPV and perovskite solar cell coatings enables efficient and precise thin film deposition. Coatema2go empowers researchers to optimize device performance and accelerate the commercialization of these next-generation PV technologies.

3rd Generation PV (OPV and Perovskite): Coatema‘s experience in OPV and perovskite solar cell coatings enables efficient and precise thin film deposition. Coatema2go empowers researchers to optimize device performance and accelerate the commercialization of these next-generation PV technologies.

![]() Flexible Displays and OLEDs: Coatema‘s expertise in flexible display and OLED coatings ensures high-quality and reliable performance. Coatema2go allows for the development and testing of new materials and processes, advancing flexible display technology.

Flexible Displays and OLEDs: Coatema‘s expertise in flexible display and OLED coatings ensures high-quality and reliable performance. Coatema2go allows for the development and testing of new materials and processes, advancing flexible display technology.

![]() Medical and Pharmaceuticals: Coatema‘s experience in pharmaceutical and medical device coatings meets stringent quality and regulatory requirements. Coatema2go provides a controlled environment for developing and testing critical coatings for drug delivery and medical devices.

Medical and Pharmaceuticals: Coatema‘s experience in pharmaceutical and medical device coatings meets stringent quality and regulatory requirements. Coatema2go provides a controlled environment for developing and testing critical coatings for drug delivery and medical devices.

![]() Printed Electronics: Coatema‘s leadership in printed electronics coating and printing makes them a trusted partner for innovators. Coatema2go facilitates the development and testing of new printed electronic devices and sensors, driving advancements in this dynamic field.

Printed Electronics: Coatema‘s leadership in printed electronics coating and printing makes them a trusted partner for innovators. Coatema2go facilitates the development and testing of new printed electronic devices and sensors, driving advancements in this dynamic field.

![]() Smart Window Films and Smart Housing: Coatema‘s expertise in smart window film coatings enables precise control over optical and functional properties. Coatema2go supports the development of innovative materials and coatings for smart homes and buildings, improving energy efficiency and comfort.

Smart Window Films and Smart Housing: Coatema‘s expertise in smart window film coatings enables precise control over optical and functional properties. Coatema2go supports the development of innovative materials and coatings for smart homes and buildings, improving energy efficiency and comfort.

![]() Wearables: Coatema‘s knowledge in printed electronics and flexible materials is ideal for the wearables market. Coatema2go enables the creation and testing of functional coatings and printed components for comfortable and high-performing wearable devices.

Wearables: Coatema‘s knowledge in printed electronics and flexible materials is ideal for the wearables market. Coatema2go enables the creation and testing of functional coatings and printed components for comfortable and high-performing wearable devices.

![]() Energy Harvesting: Coatema‘s experience in energy harvesting device coatings allows for precise deposition of functional materials. Coatema2go empowers researchers to optimize the performance of energy harvesting technologies, contributing to sustainable energy solutions.

Energy Harvesting: Coatema‘s experience in energy harvesting device coatings allows for precise deposition of functional materials. Coatema2go empowers researchers to optimize the performance of energy harvesting technologies, contributing to sustainable energy solutions.

![]() Printed Sensors: Coatema‘s expertise in printed sensor technology ensures accurate and reliable performance. Coatema2go supports the development of new and improved printed sensors for various applications, from environmental monitoring to healthcare.

Printed Sensors: Coatema‘s expertise in printed sensor technology ensures accurate and reliable performance. Coatema2go supports the development of new and improved printed sensors for various applications, from environmental monitoring to healthcare.

Accessoires

Enhance your research capabilities

Coatema2go is designed to be a versatile platform for your research needs. To maximize its potential, we offer a range of high-precision accessories engineered to deliver exceptional performance and reliability.

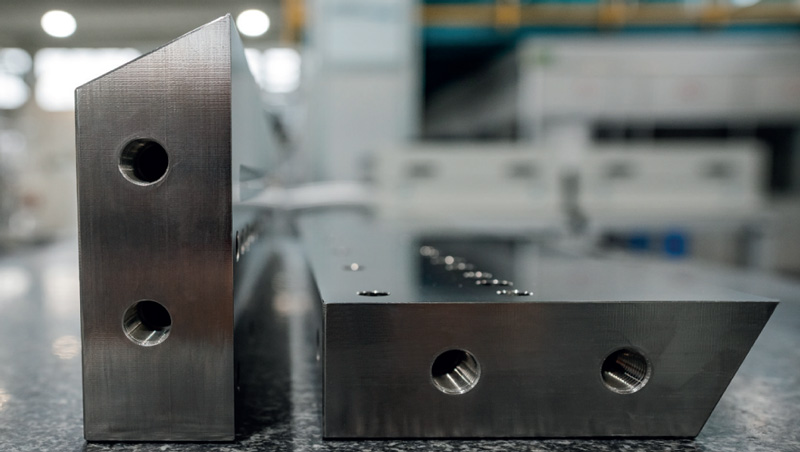

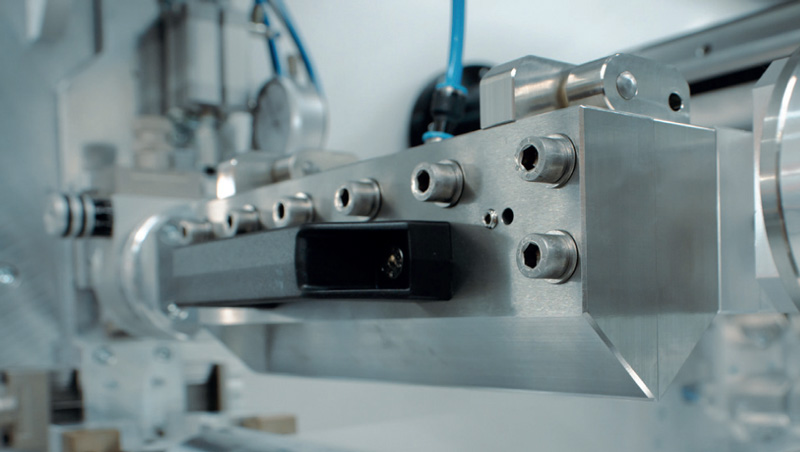

Coatema Slot dies

- Product portfolio: Available in 50 mm, 70 mm, 100 mm, 150 mm and 210 mm widths, our slot dies are manufactured to exacting tolerances, ensuring consistent coating quality and uniformity. Choose from a range of material options to suit your specific application.

- Precision engineered: We offer slot dies in A to AAA quality, guaranteeing the highest level of precision and performance for your most demanding research projects.

- Add ons: Shims of varying thicknesses are available to fine-tune coating thickness. Custom materials can be provided upon request to accommodate unique chemical or processing requirements.

- Expert support: Optimize your slot die coating process with our comprehensive slot die coating masterclass. For advanced analysis, including contact angle and fluid behavior simulations, consult our R&D centre.

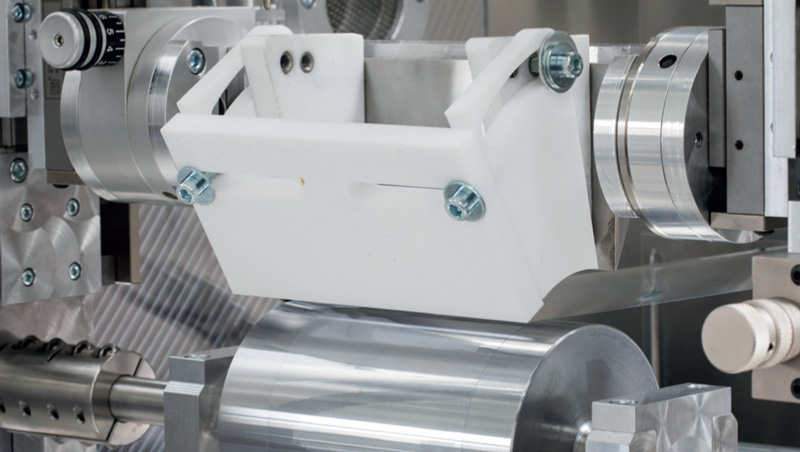

Coatema Doctor blades

- Precise metering: Available in the same sizes as our slot dies, Coatema doctor blades provide accu- rate metering and control of coating thickness.

- Versatility: Choose from 1 mm or 6 mm phases, different blade materials, and side scrapers to tailor the blade to your specific coating needs.

Coatema Comma bars

- Uniform coating: Available in the same sizes as our slot dies, our comma bars ensure consistent and uniform coating across the substrate.

- Customization: Select from a range of materials and side scrapers to optimize performance for your specific application.

Coatema Pumps

- Precision delivery: Tubes pumps are available to ensure precise and consistent fluid delivery for all coating methods.

- Smallamountsofinks: Which fit exactly to the coated area can be supplied and the pistons and tubes can be easily and fast exchanged.

- Flexibility: Piston pump integrated in #smallbutmighty #everythingyouneed #sizecounts system with option to add other syringe pump designs

Coatema Services

- R&D centre & testing – Conduct trials, optimize processes, and validate coating performance with state-of-the-art analytical tools.

- Slot Die Coating Masterclass – Gain expert knowledge on coating fundamentals, process optimization, and troubleshooting techniques.

- Custom training & development – Tailored sessions for specific applications, from material selection to advanced coating strategies.

For any questions or specialized requirements, our R&D centre is available for testing and development support. Contact us to discuss your specific needs or to schedule a visit to explore the latest coating innovations. This marks the beginning of your seamless scale-up from lab2fab: This email address is being protected from spambots. You need JavaScript enabled to view it.

Further info material

Contact

Sales & Marketing

Monday - Friday 8 am - 5 pm

Tel.: +49 (0) 21 33 / 97 84 - 222

Fax: +49 (0) 21 33 / 97 84 - 170

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Links

Articel at Pro Flexconvert:

https://m2n-converting.com/de/flexconvert/coatema2go-tabletop-coaters-feiern-ihre-markteinfuehrung/

YouTube Interview at the ICE europe 2025 with Martin Hirschmann from Pro Flexconvert:

https://youtu.be/vwNA76i3dUs