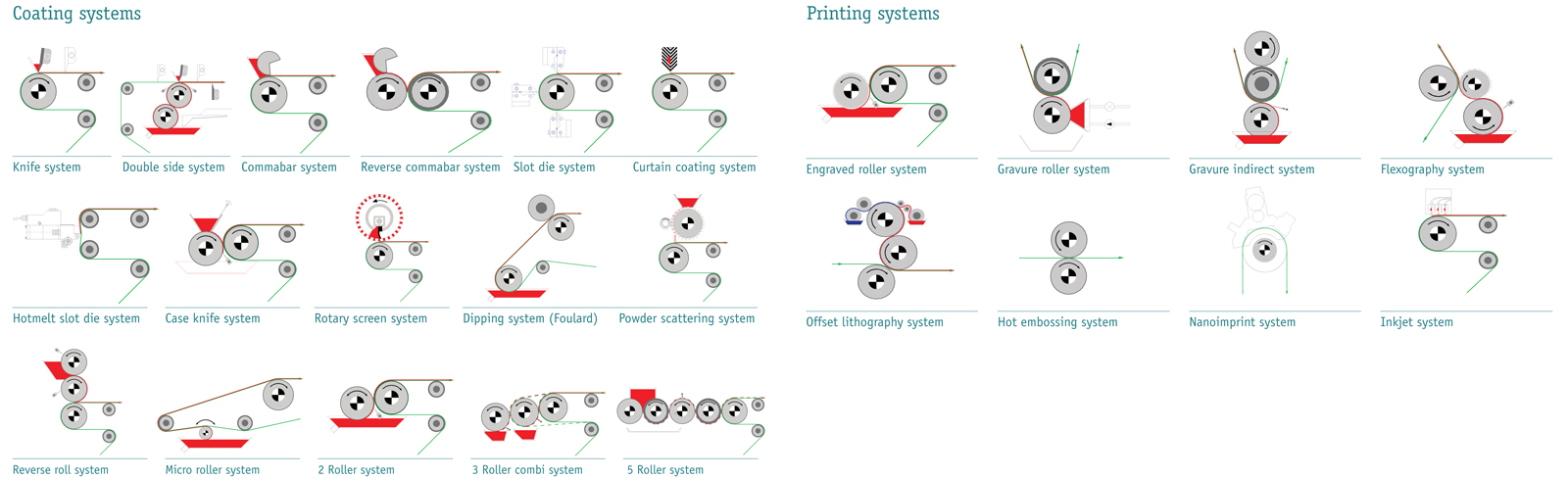

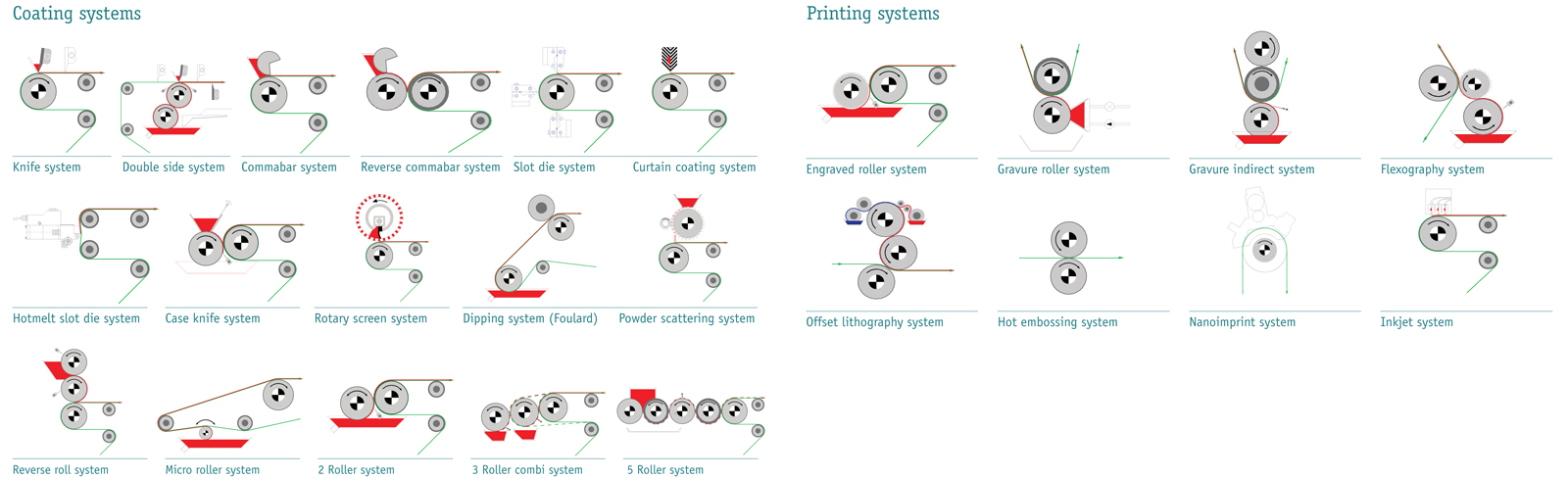

Coating systems

The right solution for every coating need:

Coatema's offers more than 35 different systems for coating and printing. The main designs are shown in sketch form here.

When it comes to coating tasks, printing processes and plant design, we have the ideal coating module for films, textiles, papers, non-woven materials and more. We can cater for continuous coating/printing and the coating/printing and lamination of single parts made from glass, metal, cardboard and other materials.

Coatema offers a wide range of application systems that can be used for the most demanding coating and printing processes. We also carry out ongoing research and development in order to improve our coating and printing systems and develop new ones.

Our main coating systems are:

Doctor blade system

Coating

Doctor blade on roller: 10 – 1,250 g/m2

Air doctor blade: 5 – 60 g/m2

Viscosity

Paste (1000): 100 – 50,000 mPas

Foam: 10,000 – 25,000 mPas

Air doctor blade: 5 – 10,000 mPas

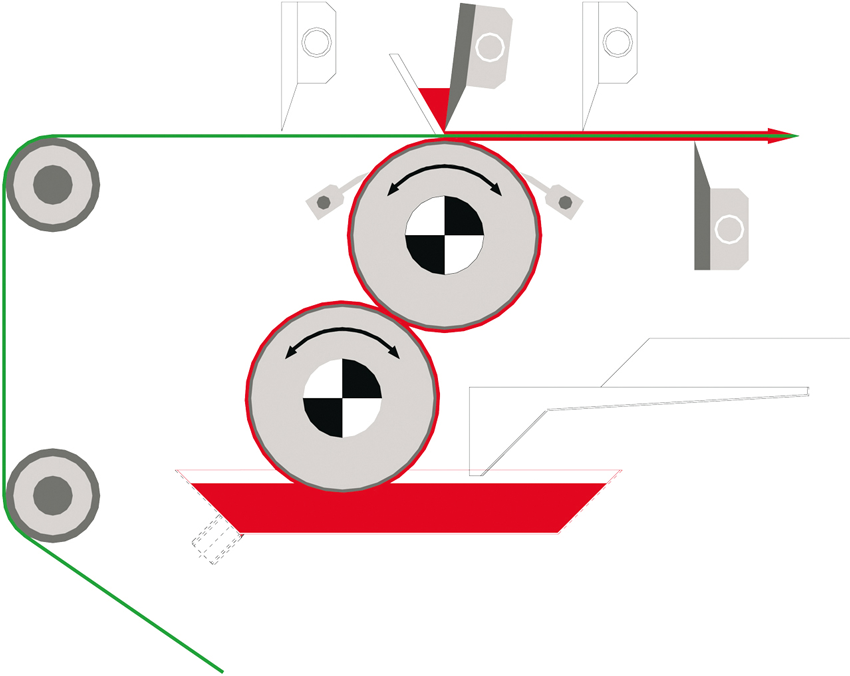

Double side doctor blade system

Coating

Doctor blade: 10 – 1,250 g/m2

Air doctor blade: 5 – 60 g/m2

Viscosity

Paste (1000): 100 – 50,000 mPas

Foam: 10,000 – 25,000 mPas

Air doctor blade: 5 – 10,000 mPas

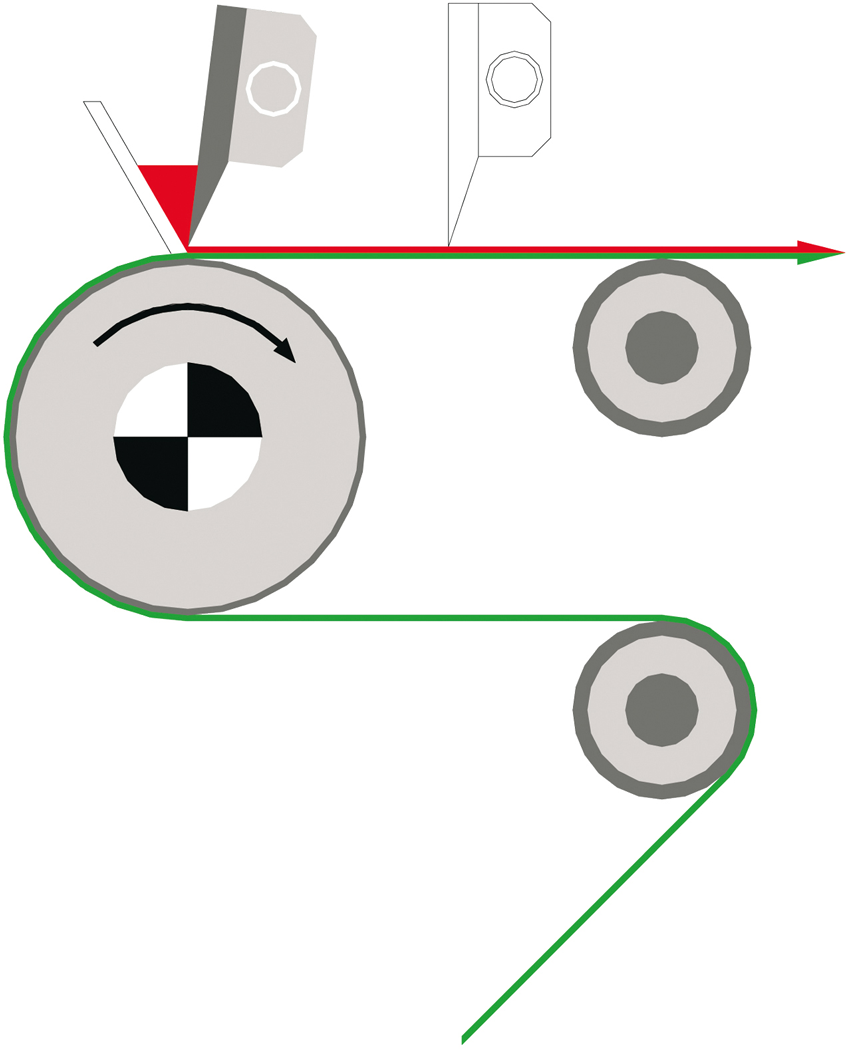

Case doctor blade

Coating

2 – 200 g/m2

Viscosity

1 – 15,000 mPas

Commabar

Coating

Air doctor blade: 5 – 1,250 g/m2

Viscosity

Paste: 5 – 60 mPas

Foam: 10,000 – 25,000 mPas

Reverse Commabar

Coating

Air doctor blade: 2 – 200 g/m2

Viscosity

Paste: 1 – 15,000 mPas

Slot die

Coating

<1 – 200 g/m2

Viscosity

1 – 30,000 mPas

Slot die (curtain coating)

Coating

10 – 300 g/m2

Viscosity

10,000 – 80,000 mPas

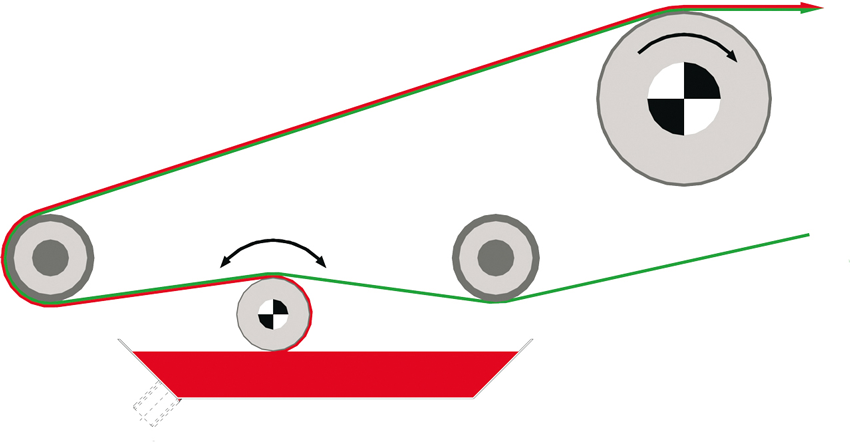

Foulard

Coating

Depending on the textile

Viscosity

1 – 10,000 mPas

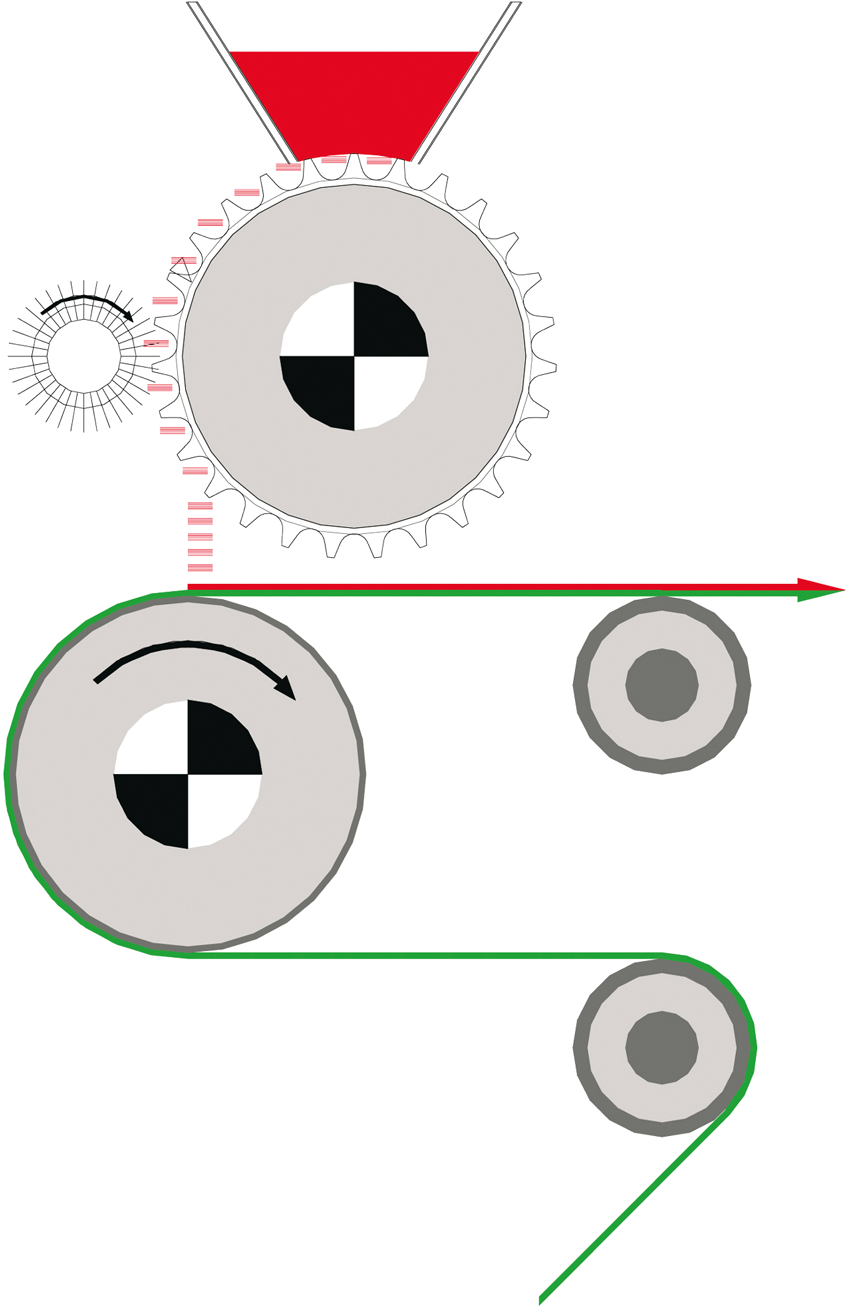

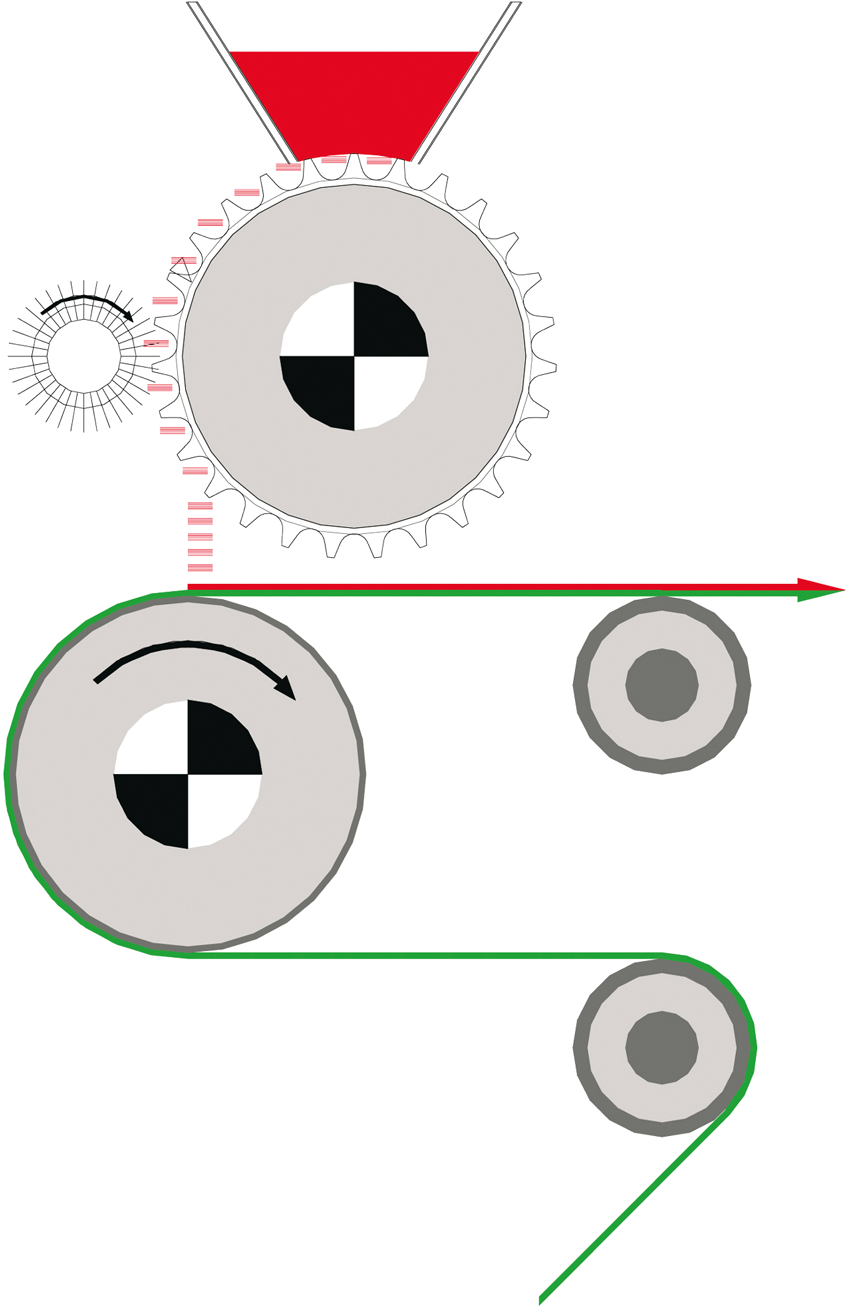

Powder scattering

Coating

10 – 300 g/m2

Viscosity

Application of powdery materials

Micro roller

Coating

2 – 100 g/m2

Viscosity

1 – 15,000 mPas

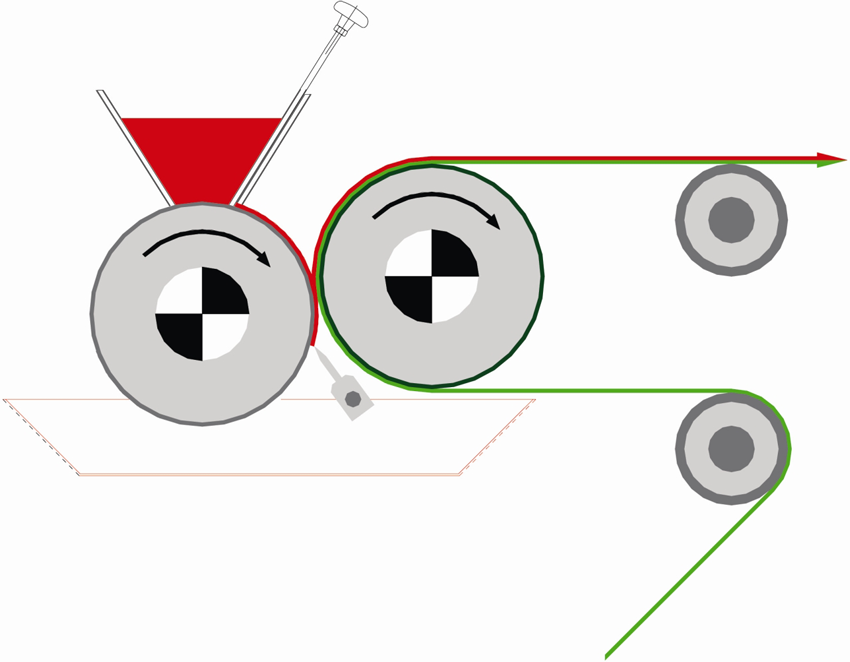

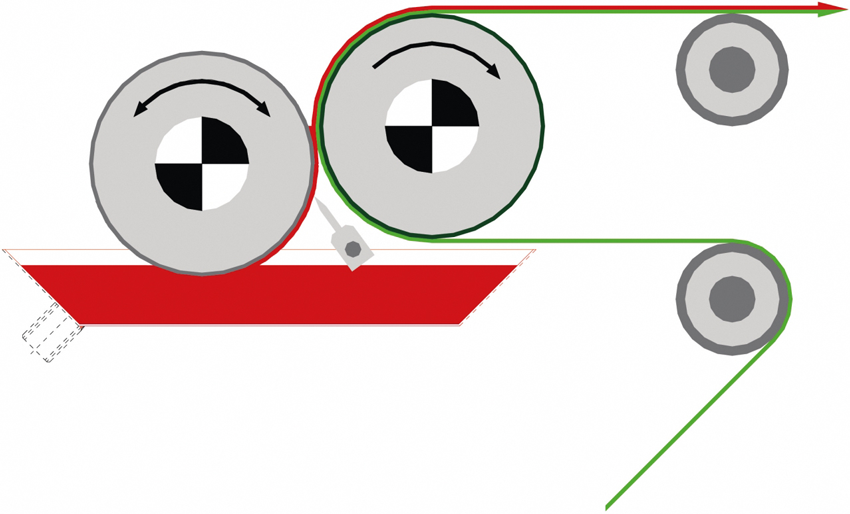

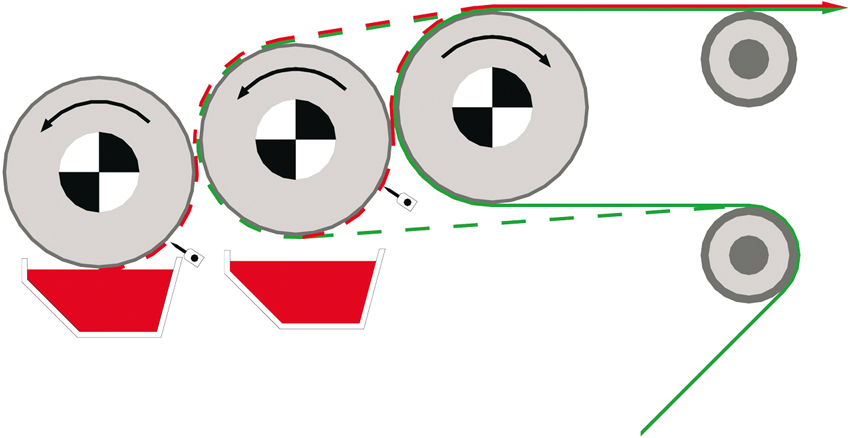

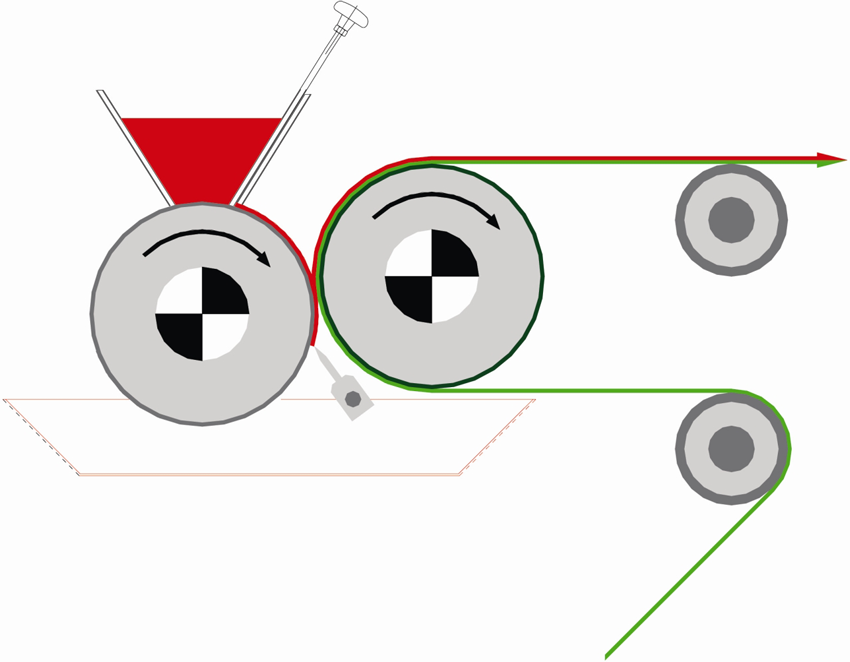

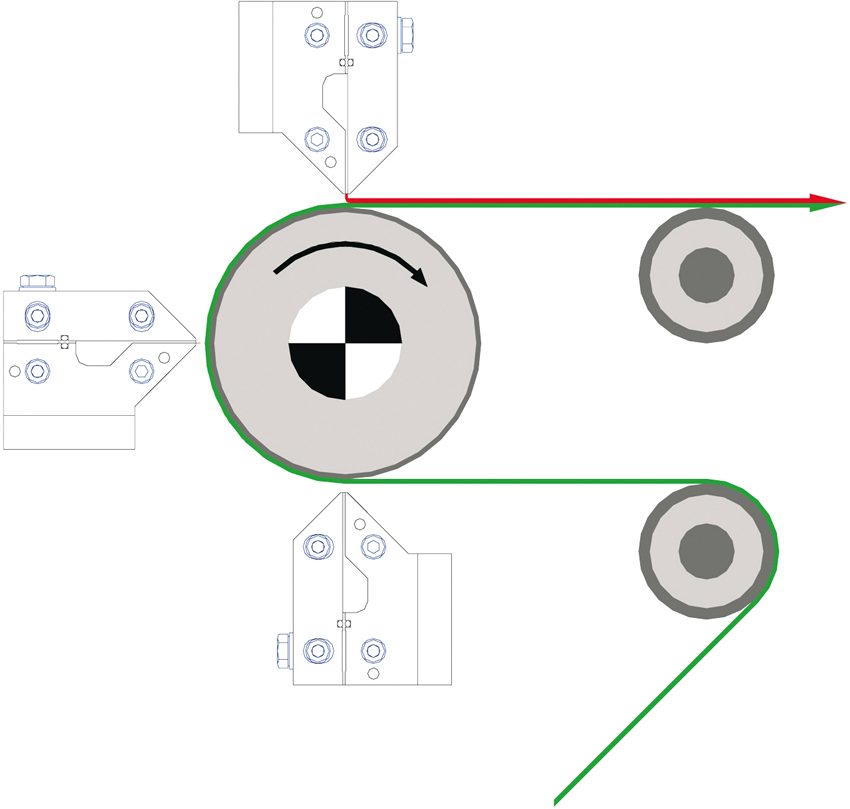

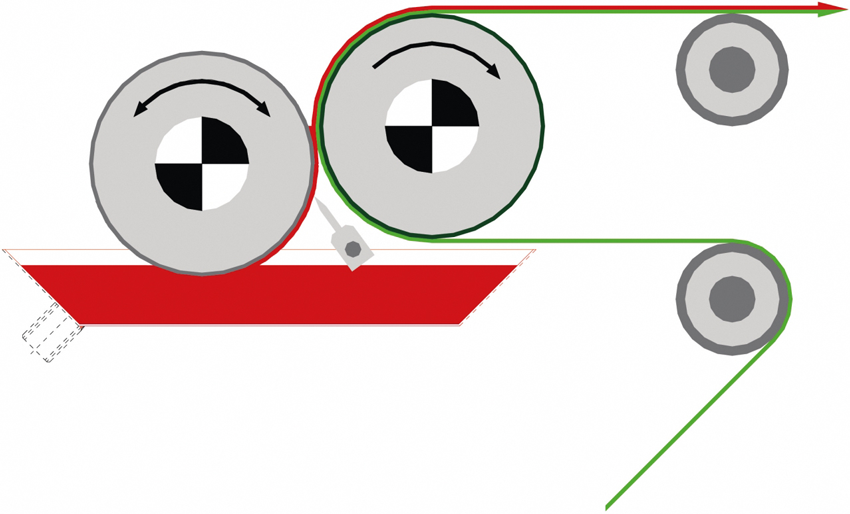

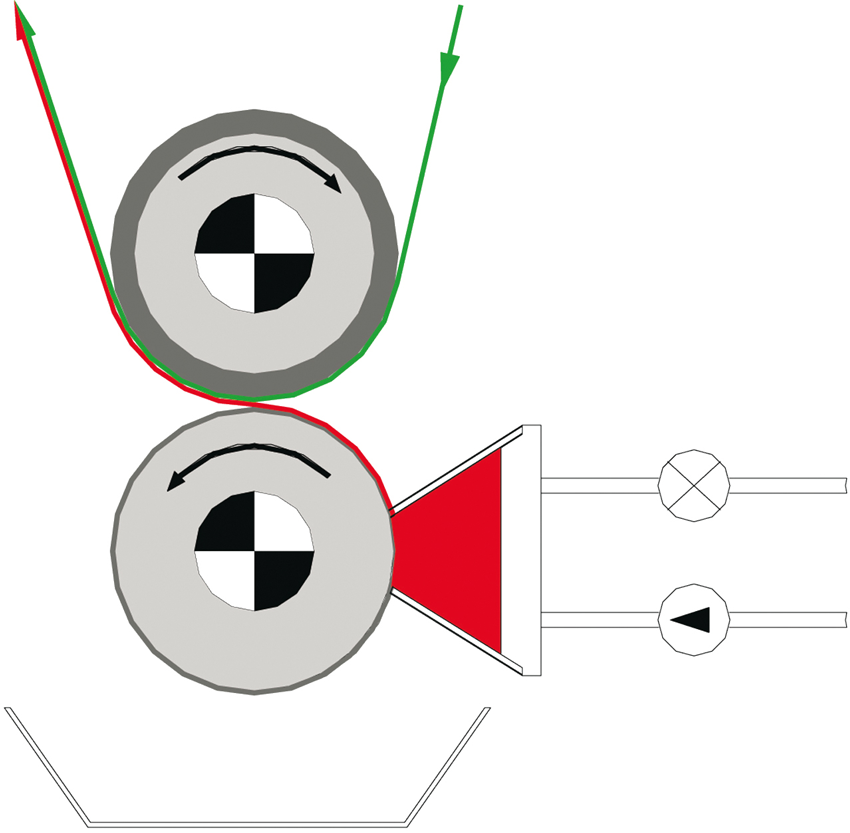

2-roller system

Coating

2 – 100 g/m2

Viscosity

1 – 10,000 mPas

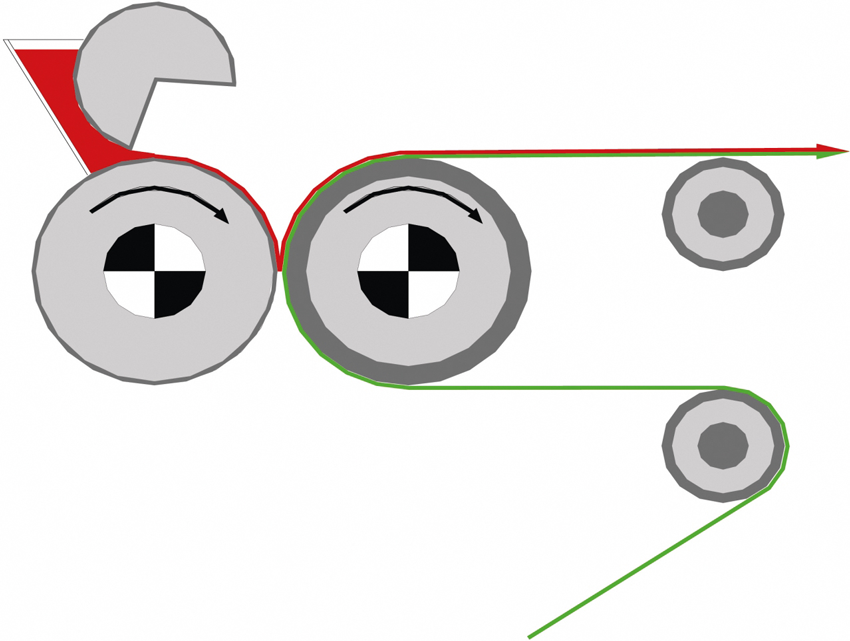

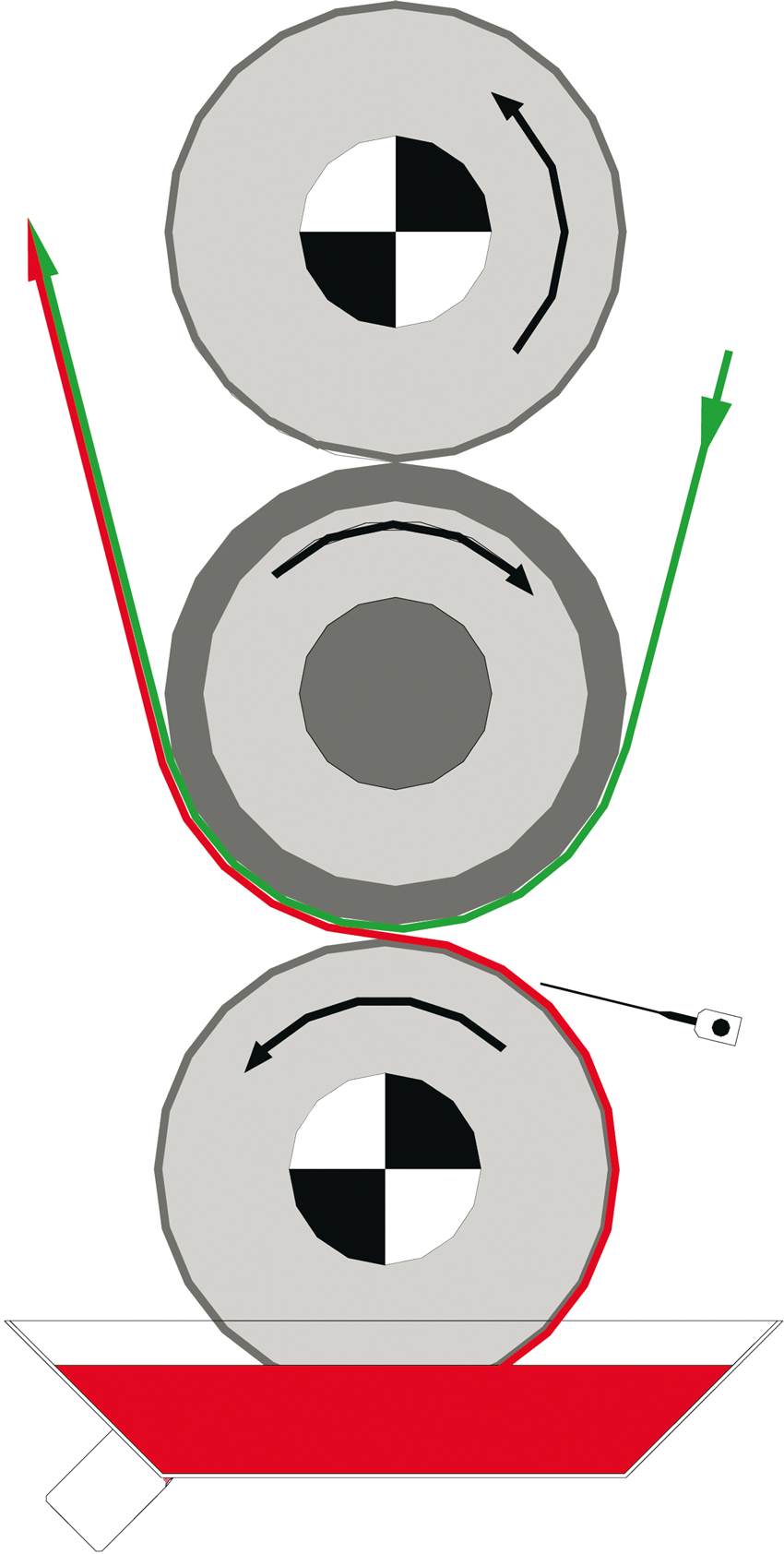

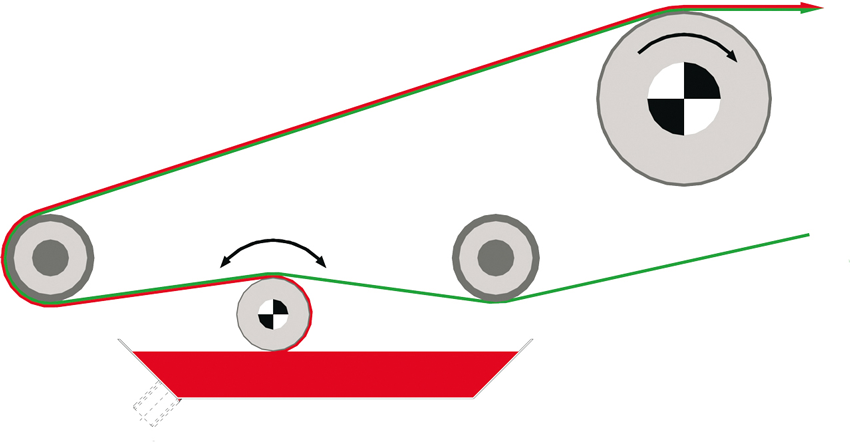

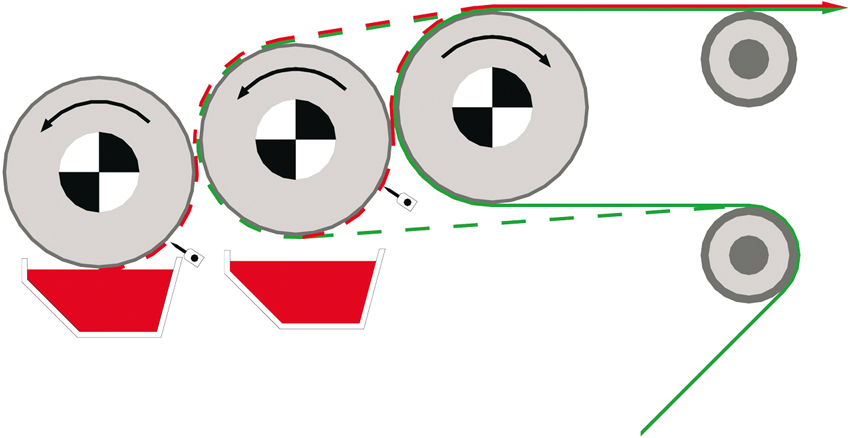

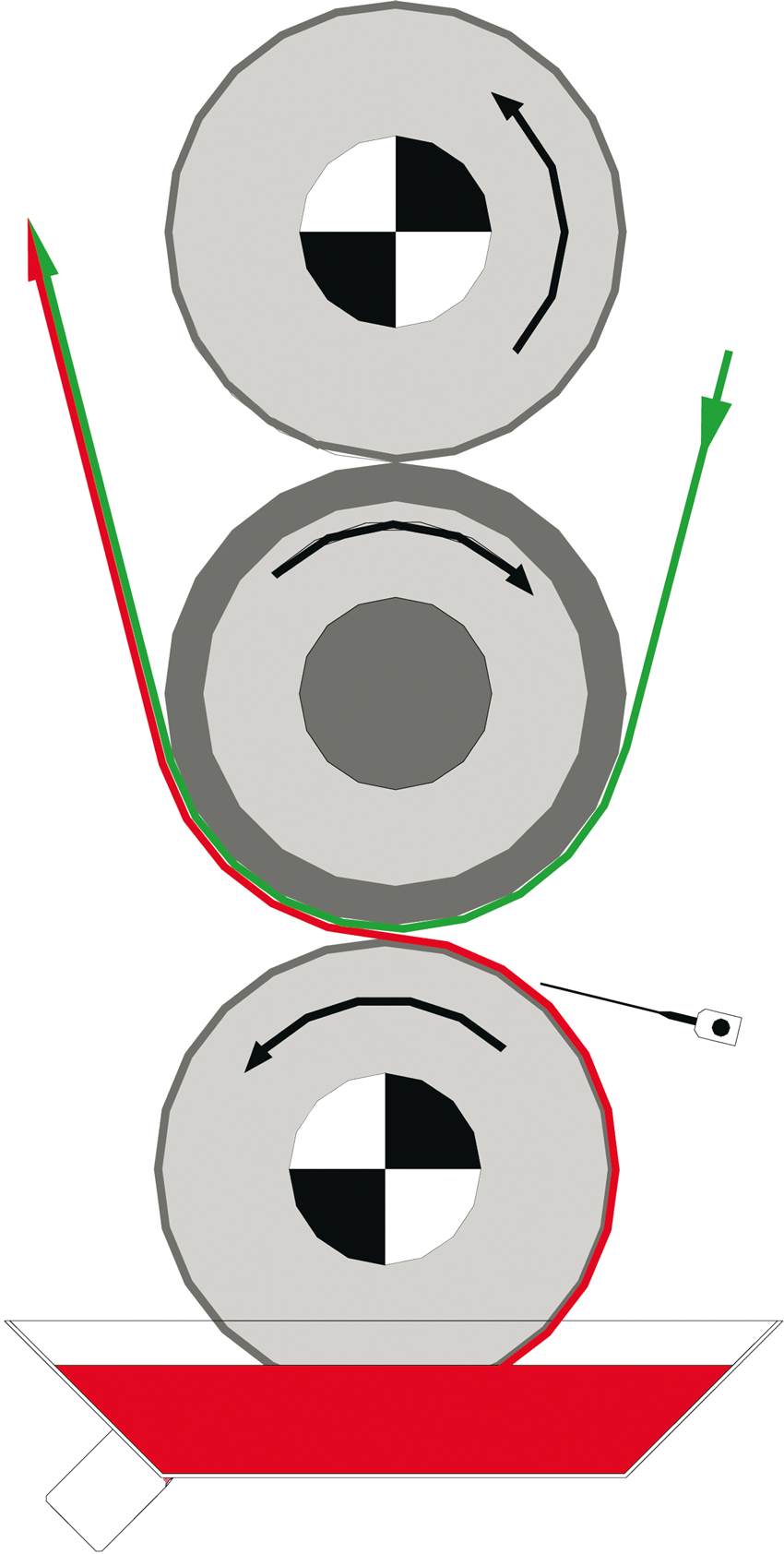

3-roller system

Coating

2 – 200 g/m2

Viscosity

1 – 15,000 mPas

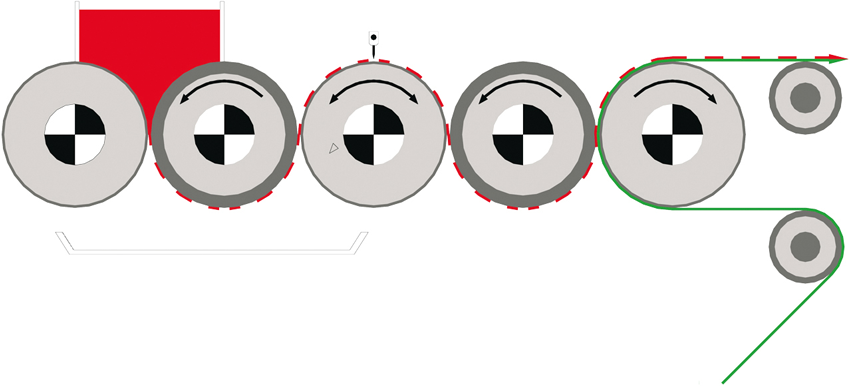

5-roller system

Coating

<1 – 10 g/m2

Viscosity

1 – 15,000 mPas

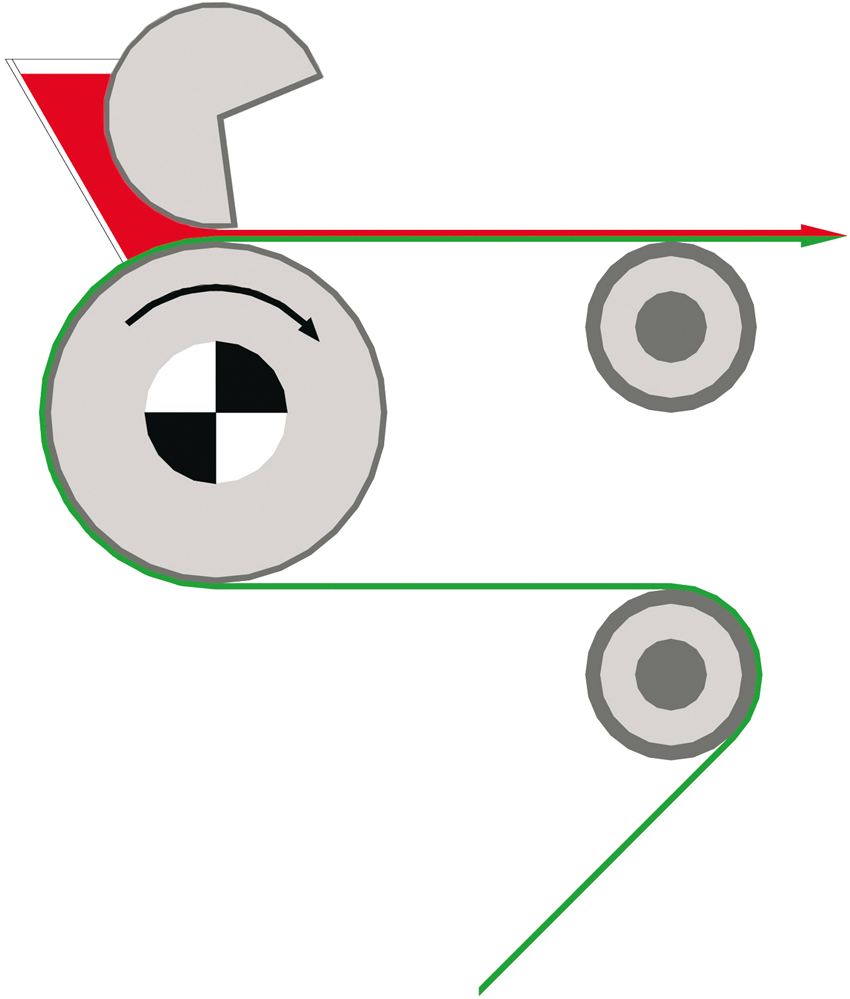

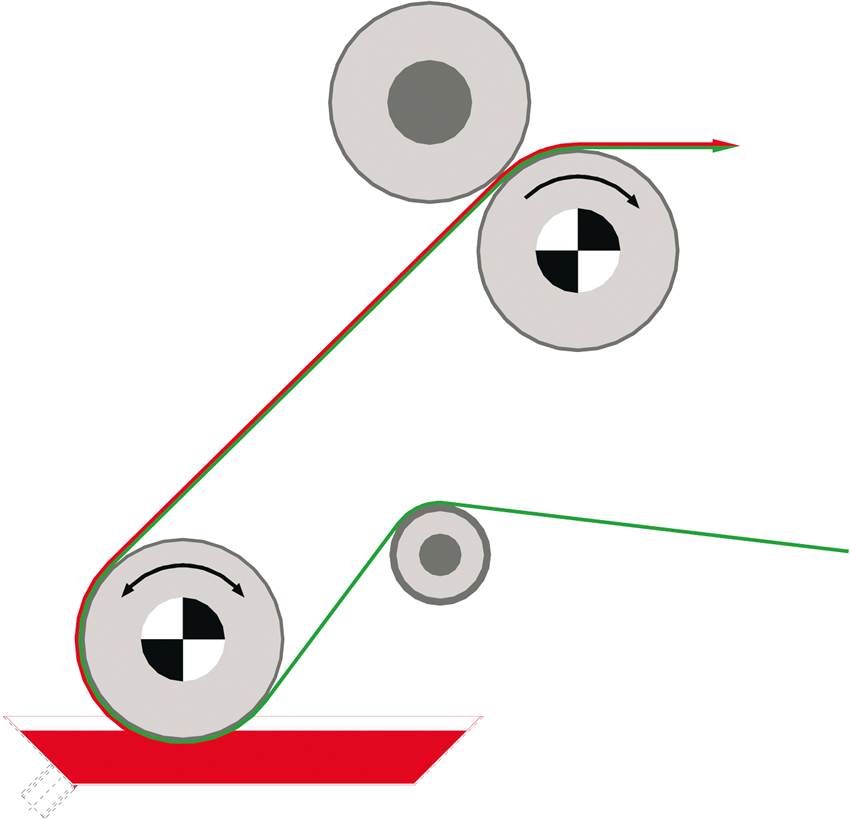

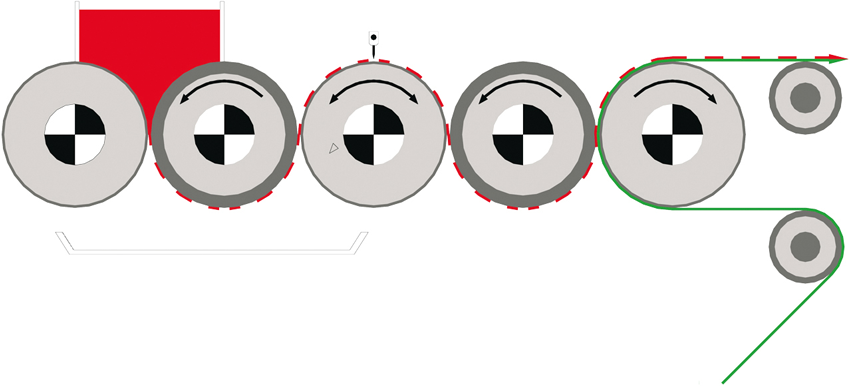

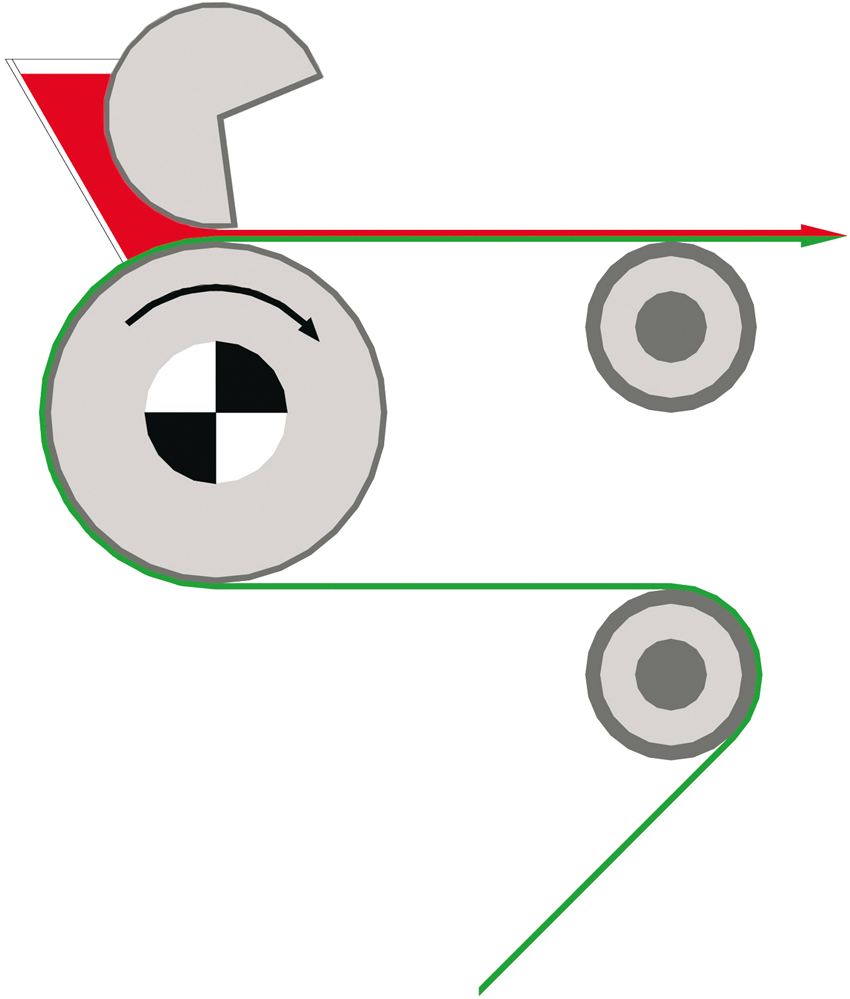

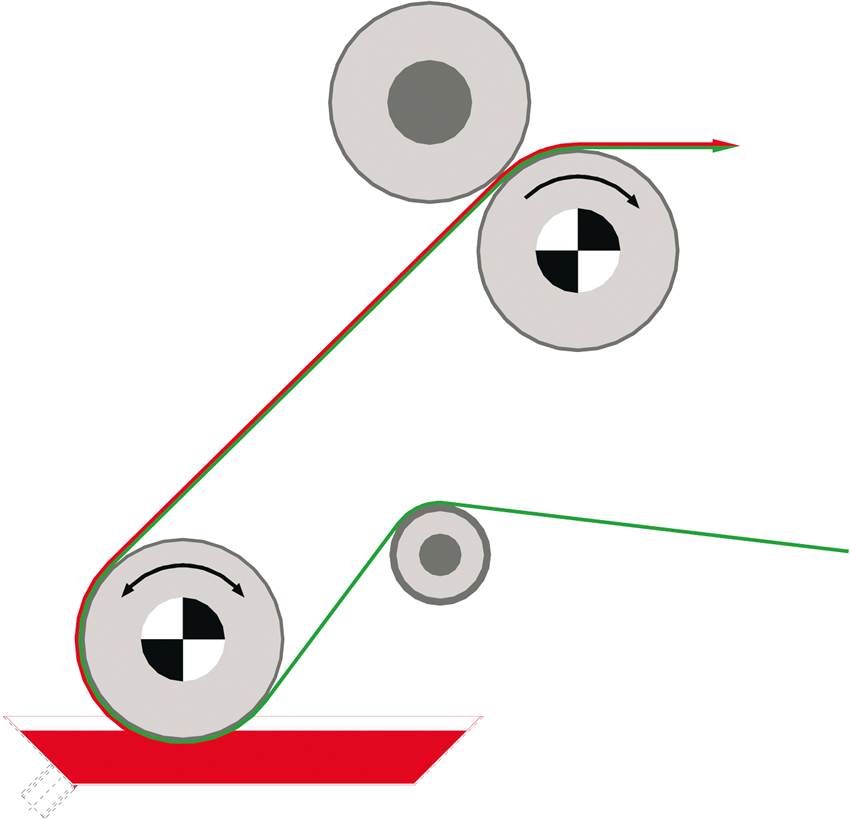

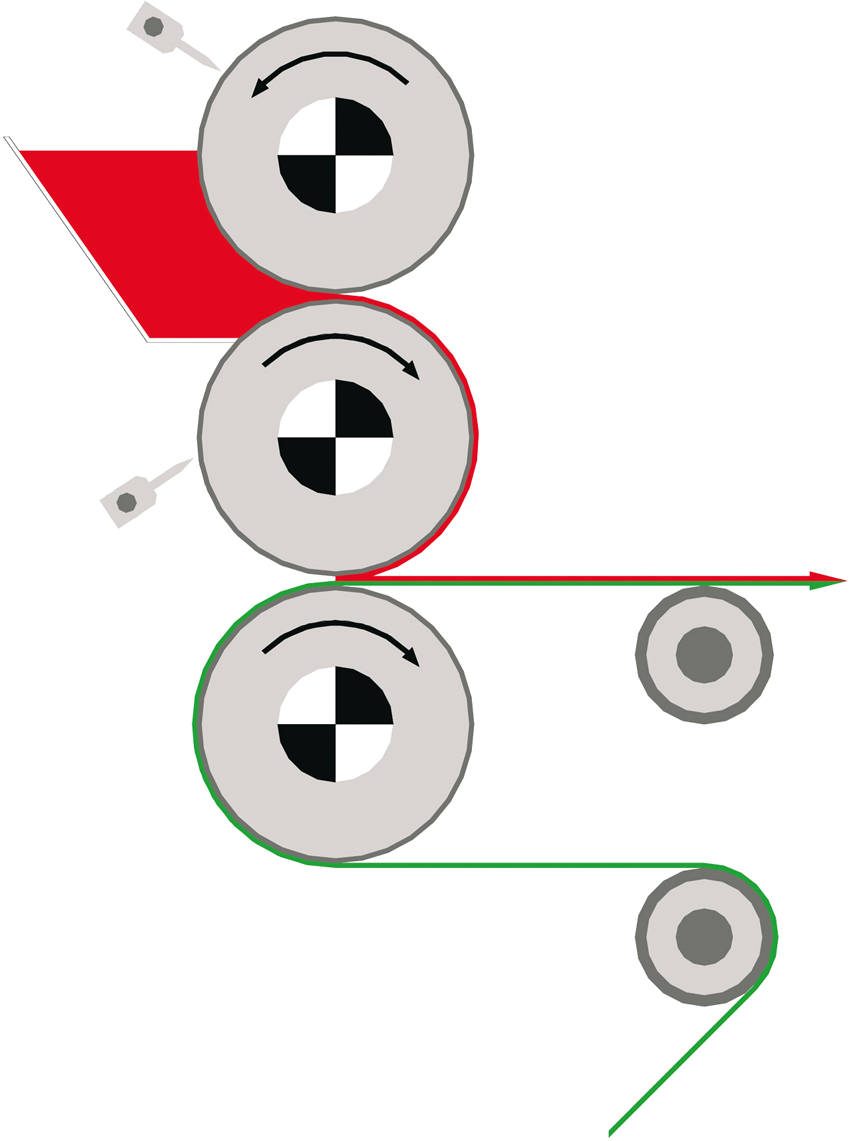

Reverse roll coater

Coating

2 – 500 g/m2

Viscosity

100 – 50,000 mPas

Our common printing systems are:

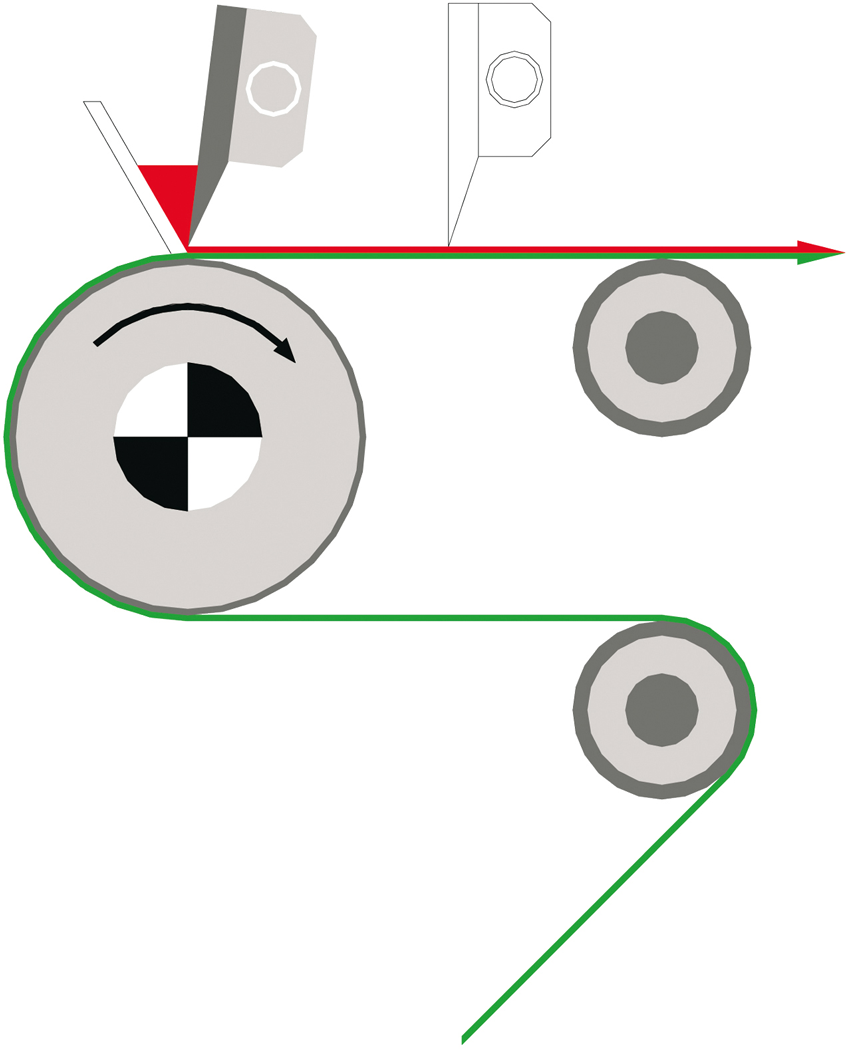

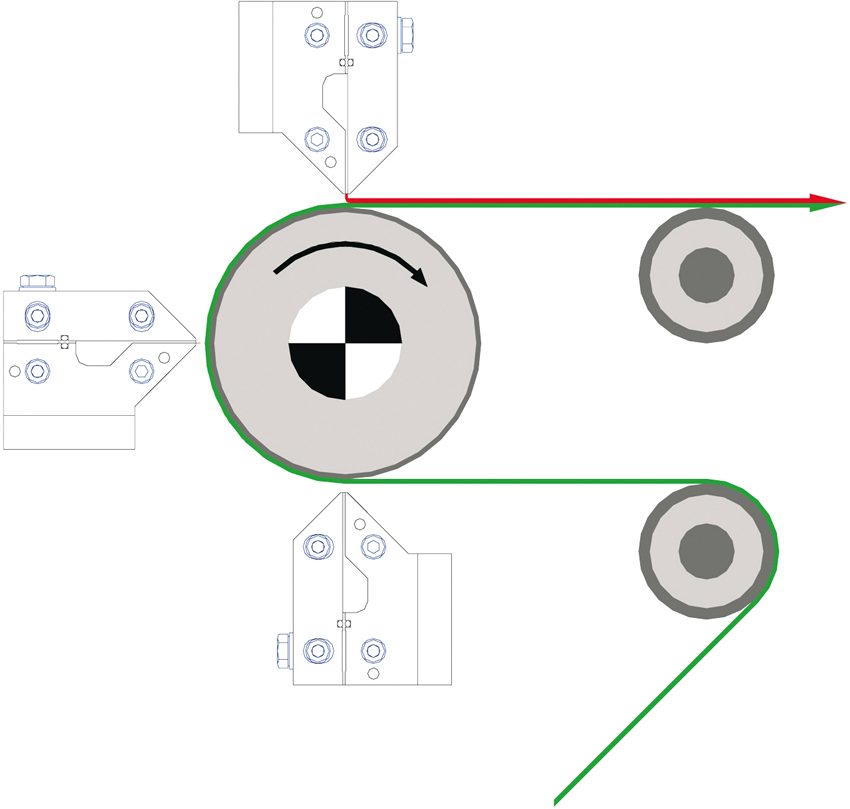

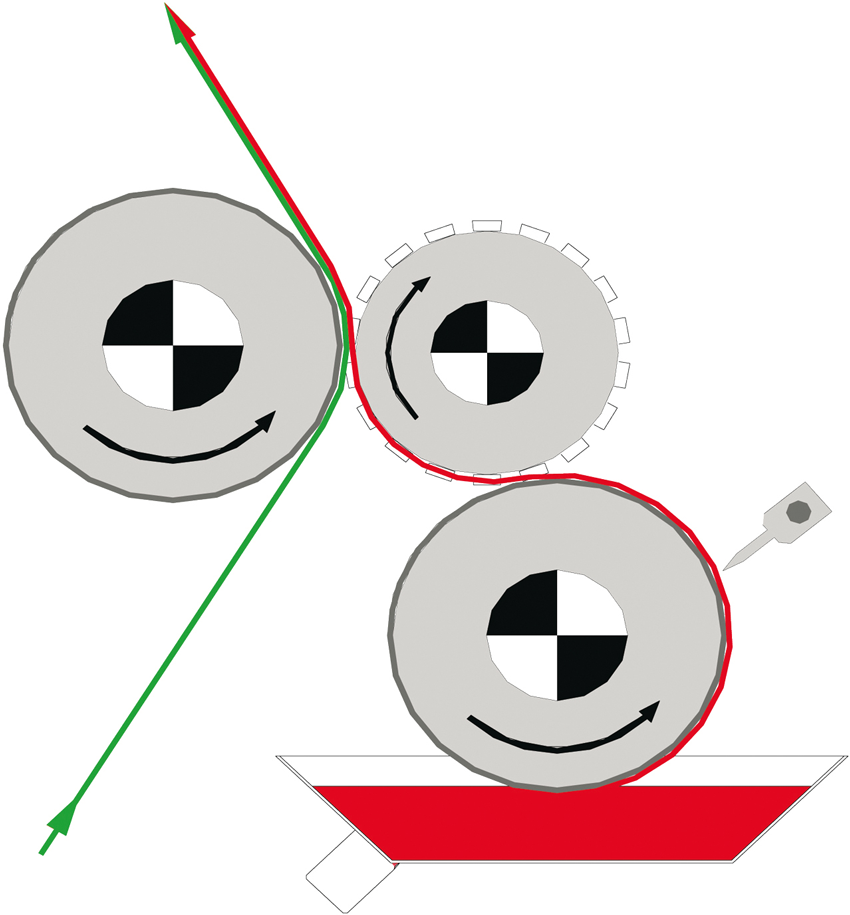

Gravure printing system

Variation of the coating weight

2 – 200 g/m2

Viscosity

1 – 15,000 mPas

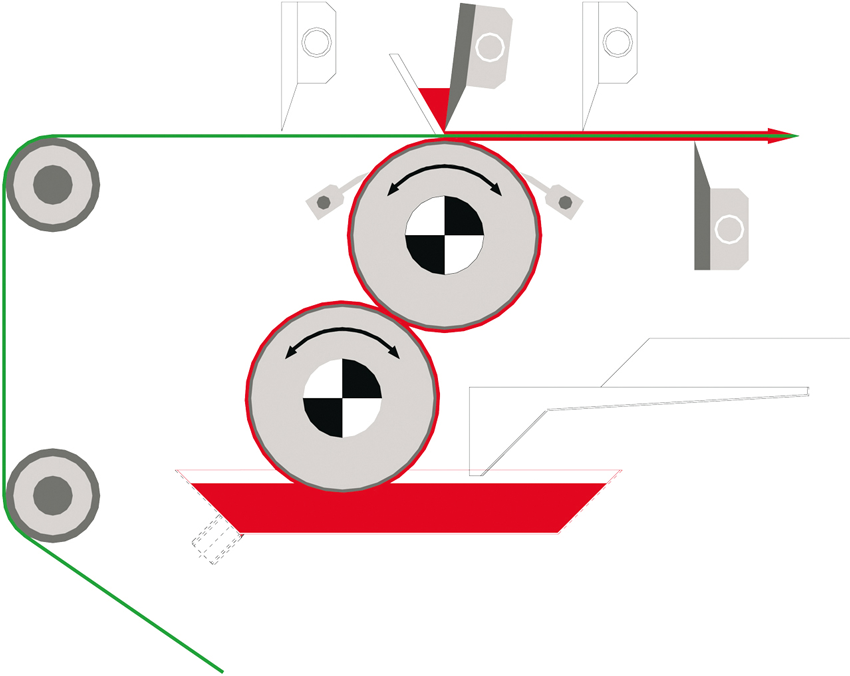

Gravure printing system (with chamber blade)

Variation of the coating weight

2 – 100 g/m2

Viscosity

1 – 10,000 mPas

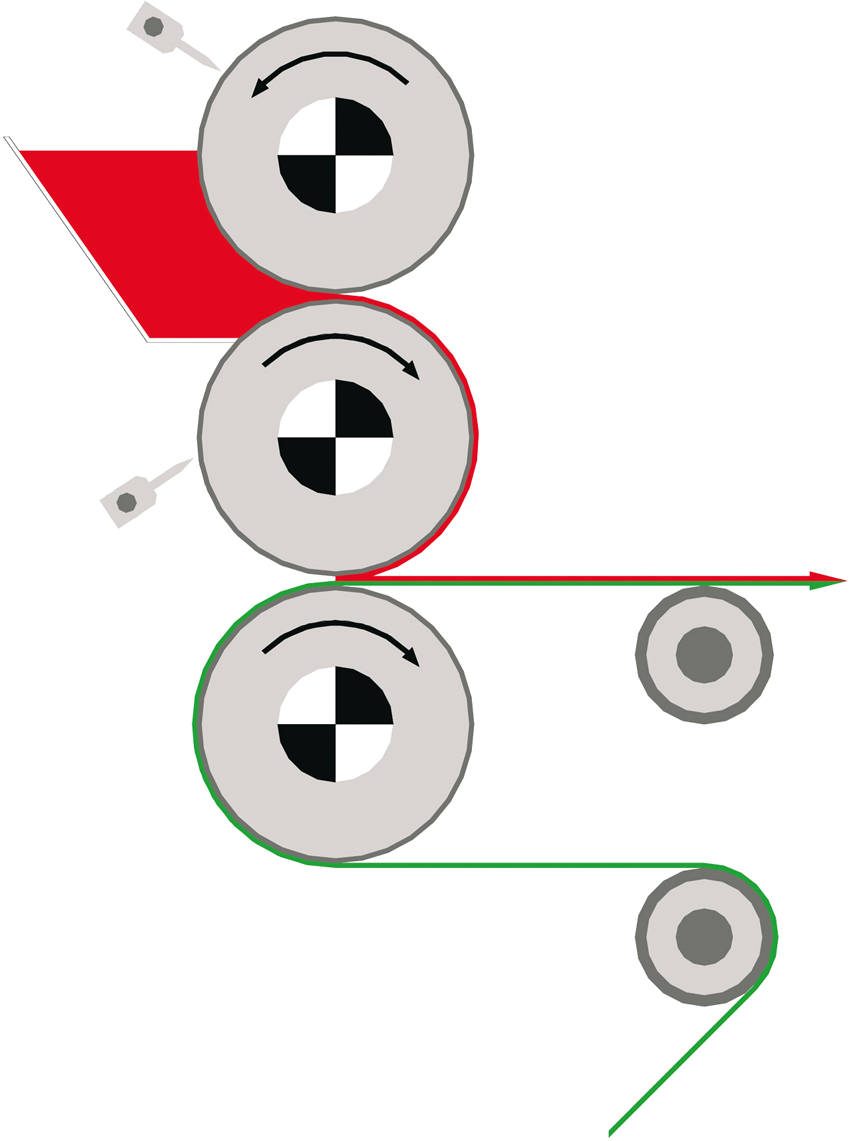

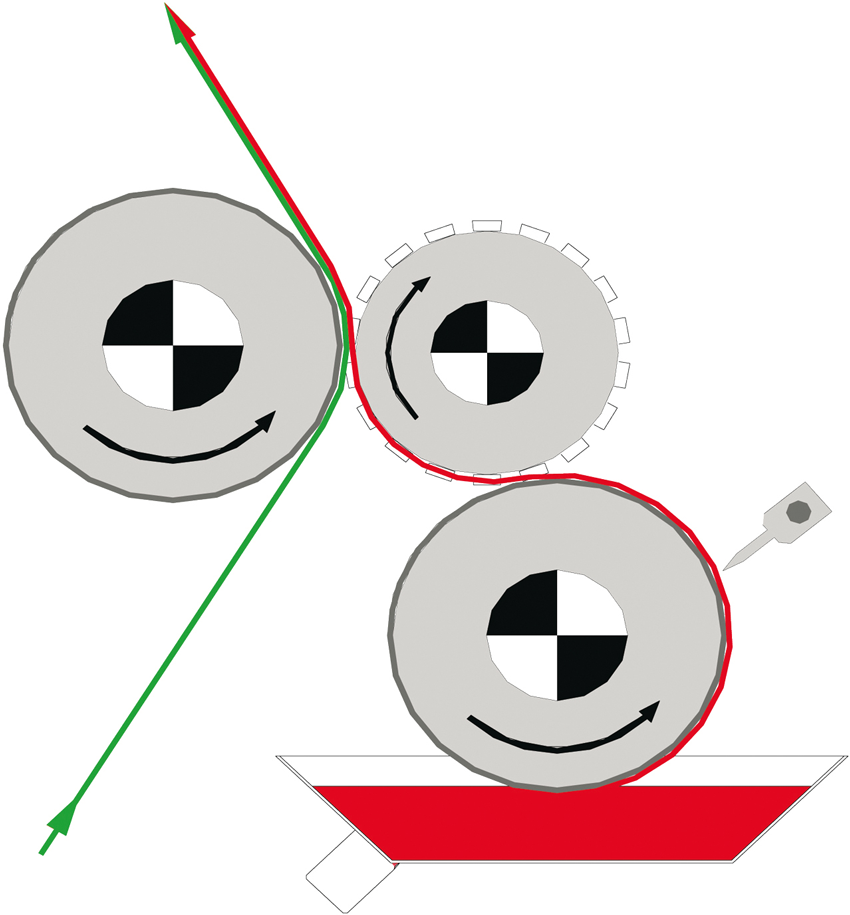

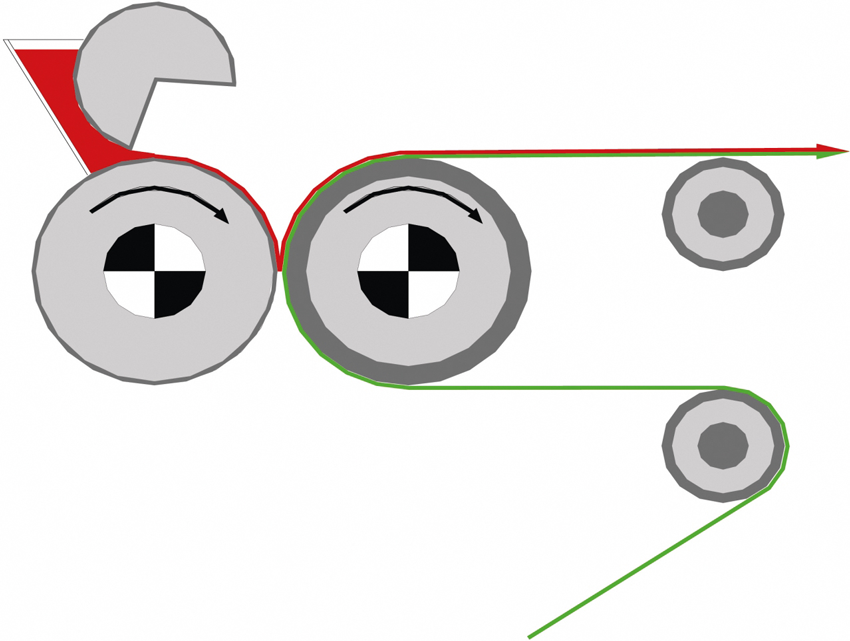

Indirect gravure printing sytem

Variation of the coating weight

2 – 500 g/m2

Viscosity

1 – 15,000 mPas

Flexo printing system

Variation of the coating weight

2 – 200 g/m2

Viscosity

1 – 15,000 mPas

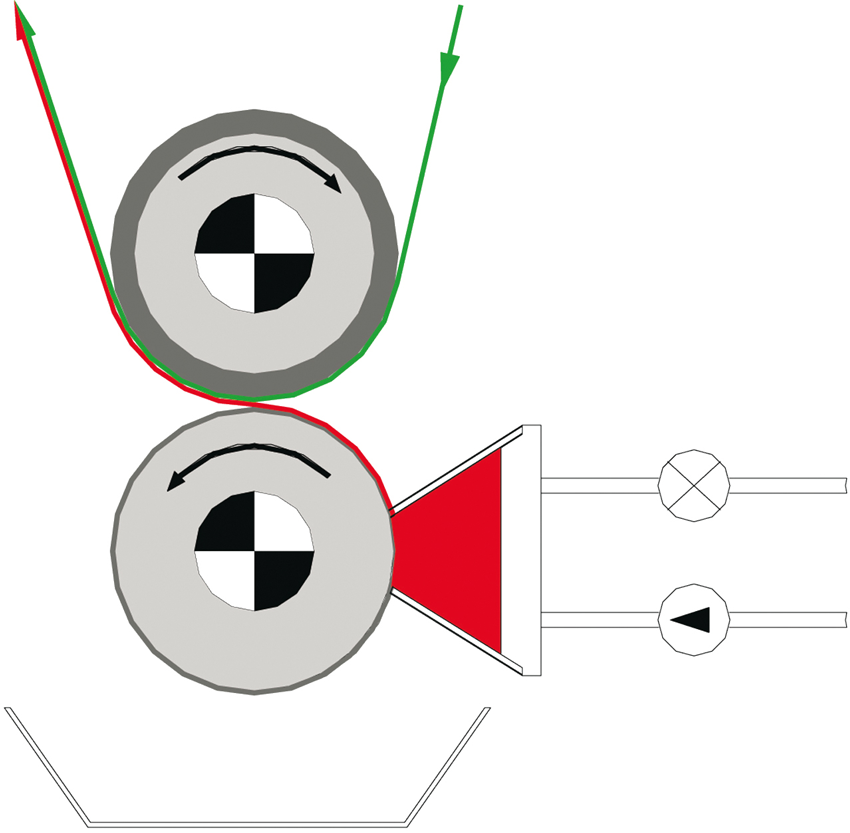

Nanoimprinting system

Variation of the coating weight

2 – 200 g/m2

Viscosity

1 – 15,000 mPas

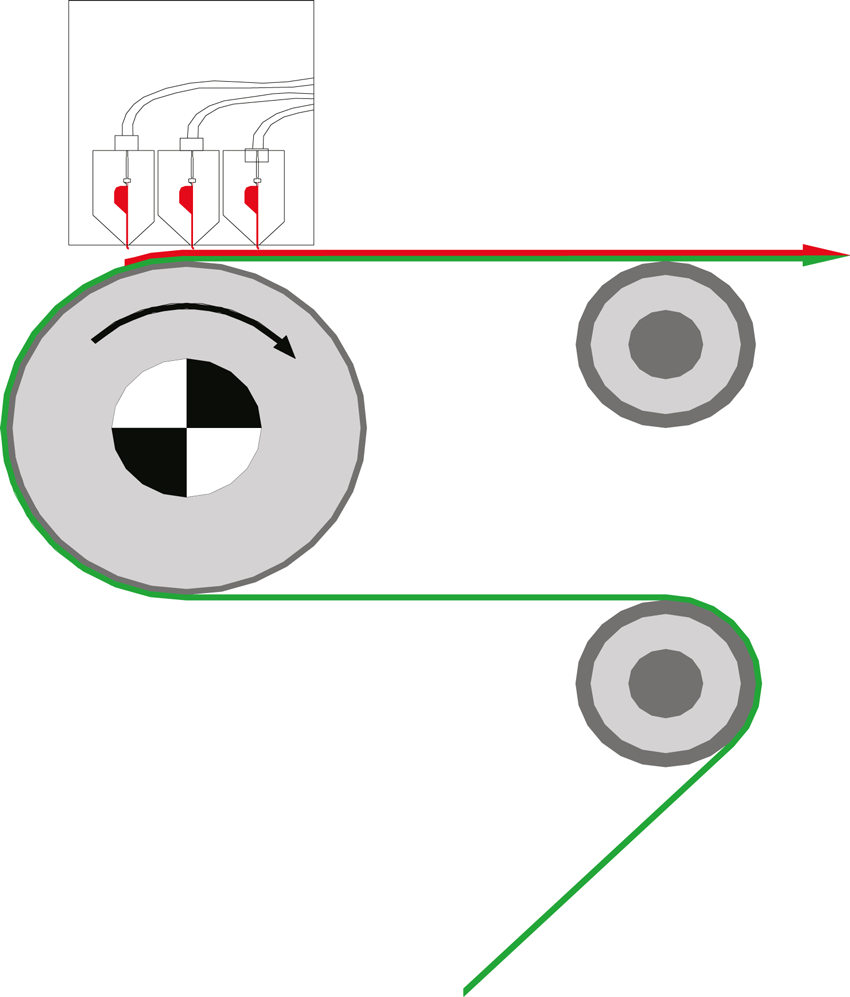

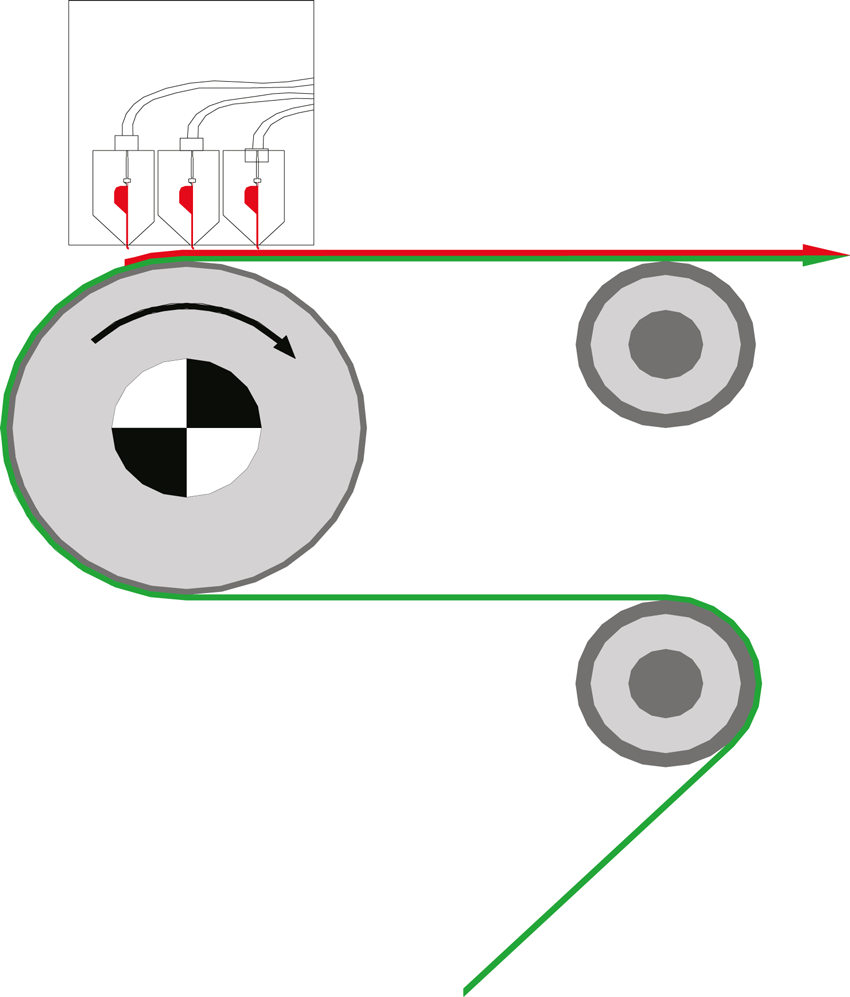

Inkjet printing system

Variation of the coating weight

2 – 200 g/m2

Viscosity

1 – 15,000 mPas