Ohio State partners with international manufacturer as new Battery Center renovations set to begin

Columbus / Dormagen, July 29th, 2024

A leading international equipment manufacturer has partnered with The Ohio State University's new Battery Cell Research and Demonstration Center, paving the way for new advancements in battery cell manufacturing needed in the electric vehicle (EV) industry, as well as expanding access to cutting-edge equipment, education and workforce training in the United States.

Germany-based partner Coatema Coating Machinery GmbH and their U.S. distributor next Machinery Group, Inc. will sponsor the acquisition of a cutting-edge equipment line for battery cell coating, which will enable users to experiment with different materials, processes and configurations at varying scales of production.

Ohio State is set to open the new $22 million, 22,000-square-foot battery center in June 2025. Managed by the Institute for Materials and Manufacturing Research (IMR), the center will accelerate domestic production of battery cell materials and manufacturing technologies, while also serving as a hands-on training hub for workforce development in advanced battery technology.

“This partnership with Coatema and next Machinery Group will substantially boost the Battery Center’s capability to provide access to state-of-the-art technology, expertise and support for battery manufacturing research,” said battery center acting director Jay Sayre, who also serves as IMR director of innovation. “This collaboration will enable the center to conduct larger-scale experiments, optimize production processes, and accelerate the development of advanced battery technologies. It will bring academia and industry closer together, which strengthens Ohio State’s leadership in battery research and development and boosts U.S. production capacity for EV batteries.”

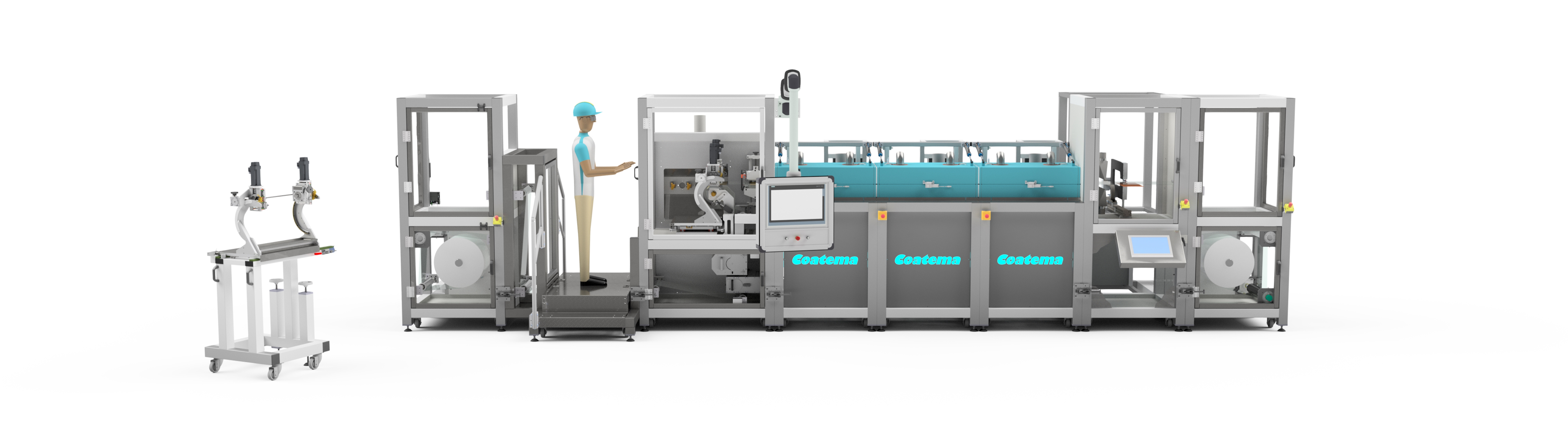

With the center’s goal to bridge the gap between fundamental research and battery cell manufacturing, Coatema’s Click&CoatTM machine line will serve as an integral set of tools in the development of high-quality, consistent battery cells for the market.

Coatema cutting edge Click&CoatTM line for The Ohio State University ©Coatema Coating Machinery GmbH

University researchers, students and industry users will be able to customize the coating configurations of the new machine line to scale to the scope of their specific project, from the lab to pilot production line.

“We are excited to collaborate with The Ohio State University on this groundbreaking project. Our Click&CoatTM machine line will empower researchers and industry professionals with the tools needed to advance battery cell manufacturing, ultimately driving innovation in the EV sector,” said Thomas Kolbusch, VP of Coatema Coating Machinery GmbH.

The partnership also brings a new opportunity to connect around state-of-the-art equipment, bringing Coatema R&D teams and other industry users from Germany to train and demonstrate system capabilities alongside Ohio State faculty and students.

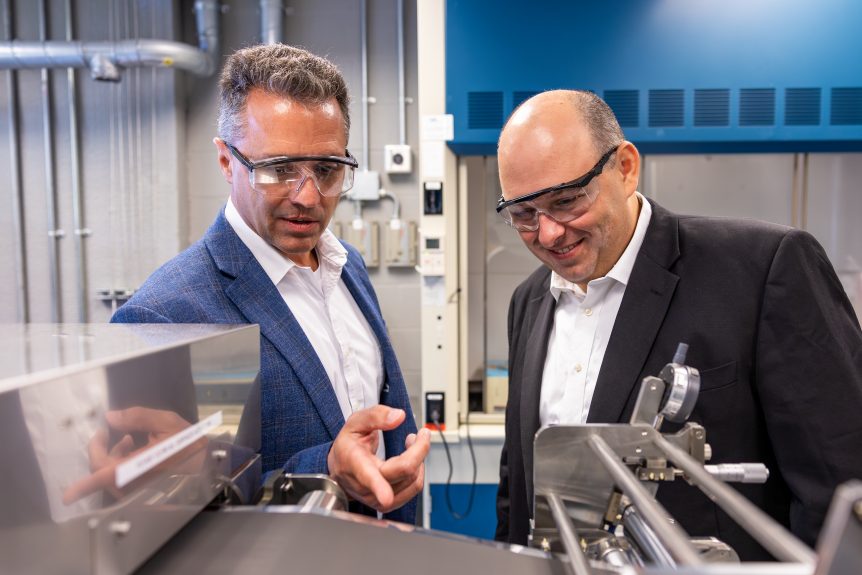

OSU’s battery center acting director Jay Sayre, with Congresswoman Joyce Beatty, Congressman Mike Carey, Coatema’s VP Thomas Kolbusch and the next Machinery Group team led by Tomi Belosevic at the announcement ceremony in Columbus, OH Photo credit Emma Parker

In addition to workforce training for specific system use and automakers transitioning to EV manufacturing, the center will serve as a learning space for students in materials, manufacturing, and beyond, offering internships and other experiential learning opportunities in a rapidly evolving, clean-tech manufacturing environment.

“Having this capability will allow students the opportunity for hands-on training, interdisciplinary collaboration, and project-based learning that will foster a skilled workforce capable of advancing EV technology and translating research into real-world applications,” Sayre said.

Honda, the lead foundational partner, has committed $15 million to the research and development center, while Schaeffler Americas also serves as a foundational partner. Federal funding for the center was provided through the National Institute of Standards and Technology’s (NIST) Extramural Construction program, thanks to the efforts of congressional champions U.S. Sen. Sherrod Brown and U.S. Reps. Joyce Beatty and Mike Carey. The project was also endorsed by the State of Ohio and JobsOhio.

About next Machinery Group, Inc.

next Machinery Group is Coatema’s North American distributor specializing in coating, printing, and lamination solutions, with a strong focus on battery, fuel cells, electrolyzer, solar, and printed electronics technologies. Their comprehensive range of machinery and technologies is designed to optimize these critical manufacturing processes for innovative industries, start-ups, and research institutions. With a commitment to innovation, quality, flexibility, and sustainability, next Machinery Group serves a diverse clientele across various industries, driving progress and efficiency in manufacturing. Contact This email address is being protected from spambots. You need JavaScript enabled to view it. for more information. www.next-mg.com

About Coatema Coating Machinery GmbH

As the one stop shop solution for your lab2fab scale up Process, Coatema develops and builds lab, pilot, and production equipment for coating, printing, and laminating processes with more than 40 years of experience in sectors such as batteries, fuel cells, electrolyzers, solar and printed electronics. With a leading R&D center in Dormagen, Germany, the Coatema is internationally recognized for its innovations in high tech markets with its versatile and modular equipment solutions. www.coatema.de

More informations on the website from the OSU University:

https://imr.osu.edu/ohio-state-partners-with-international-manufacturer-as-new-battery-center-renovations-set-to-begin/

Story by IMR communications coordinator Mike Huson. Contact: This email address is being protected from spambots. You need JavaScript enabled to view it..