The Roll-to-Roll (R2R) Process in Industrial Scale-Up

The Roll-to-Roll (R2R) Process in Industrial Scale-Up: A Comprehensive Examination of Its Impacts and Challenges

Oktober 2023 - By Thomas Kolbusch, Director of Sales, Marketing, and Technology, VP | Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

1. Abstract

The Roll-to-Roll (R2R) processing methodology, pivotal in the fabrication of printed electronics, particularly 3rd Gen photovoltaics (OPVs), offers significant advantages. Yet, inherent technical challenges pose constraints in achieving optimal device performance. This article delves into the mechanics, advantages, and impediments associated with the R2R method as applied to OPVs.

2. R2R Process: Operational Mechanics and Implications

2.1. Mechanism

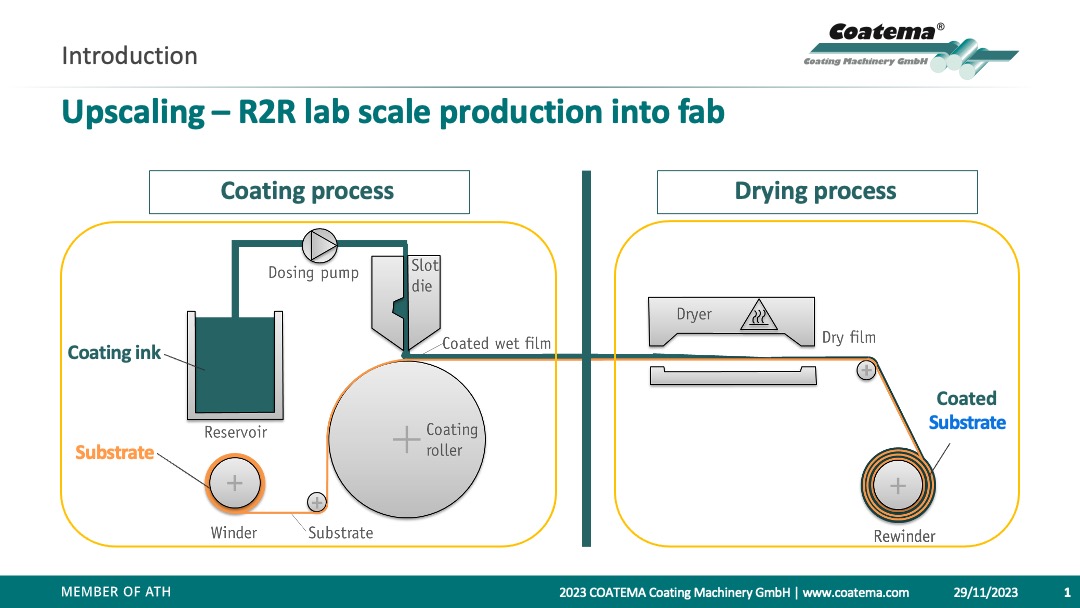

At its core, R2R involves unreeling a flexible substrate from a source, subjecting it to various fabrication processes, and subsequently reeling the treated substrate. These processes can encompass material deposition, lithographic patterning, and post-fabrication treatments.

2.2. Benefits

- High Throughput: Continuous production translates to faster manufacturing cycles..

- Economic Viability: Economies of scale achieved reduce per-unit costs.

- Versatility: It enables the creation of lightweight, flexible electronic devices.

3. Inherent Technical Challenges in R2R Processing for OPVs

3.1. Ensuring Quality Homogeneity

Attaining uniformity in deposition across vast substrate lengths poses a formidable challenge. Factors like deposition rate, substrate tension, and ambient temperature can influence the end product's quality.

3.2. Addressing Material Limitations

For OPVs, the choice of materials is critical. Many organic materials used in these cells are sensitive to environmental factors like humidity and temperature. The R2R process, being continuous, requires that these materials remain stable over extended periods, a challenge that is currently under intensive research

3.3. Guaranteeing Consistent Device Performance

Securing uniform device efficiency across an extended substrate requires rigorous quality control. Discrepancies in layer composition or thickness can culminate in efficiency variations, detracting from the overall process yield.

4. An Analysis of Two Decades of OPV Advancements

Over the preceding 20 years, significant strides have been made in OPV technology

- Material Evolution: Introduction of novel organic compounds to enhance light absorption and electron mobility.

- Architectural Refinements: Tandem structures, where multiple OPV layers are stacked, have emerged to enhance the cell's absorption spectrum

- Optimization of R2R Processes: Advancements in substrate control, improved coating and printing techniques, and swifter post-deposition treatments have been established.

Despite these advancements, the conversion efficiency of R2R-produced OPVs remains an area of ongoing research when compared to other photovoltaic technologies.

5. Summary

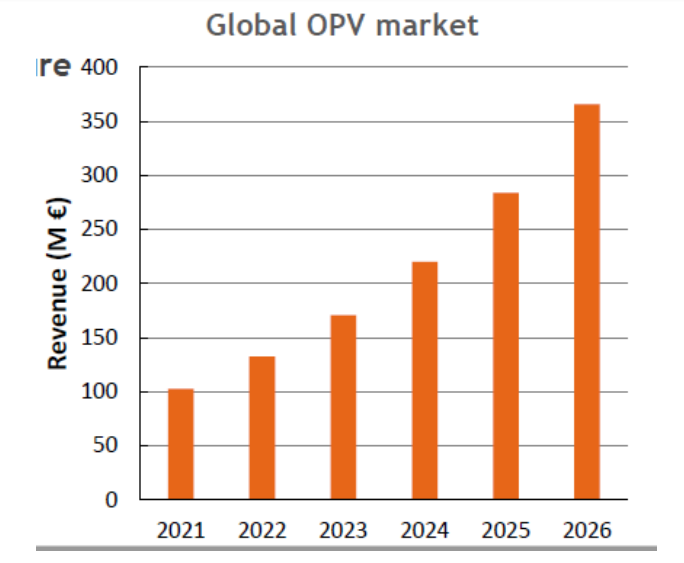

The potential of the R2R process in reshaping printed electronics production is clear. However, its broader adoption, especially for OPVs, demands a precise understanding of its challenges and a continuous drive for research and innovation. The advancements over the past 20 years underline the ongoing effort in this field and the need for further refinement to fully exploit R2R's benefits in OPV manufacturing. Coatema is working on all of these topics with cooperation partners in R&D and industry and with the Horizon Europe project Flex2Energy will establish a production line for OPV in Greece with integrated module assembly. This will be a boost to the European efforts to be more independent from imports from China.

Growth rate of the global OPV market