Nächstes Symposium

Das 24. internationale Symposium für Beschichten, Drucken und Laminieren

Seit dem Jahr 2000 ist das internationale Coating Symposium für Beschichten, Drucken und Laminieren ein fester Bestandteil in der Branche.

Vortragende aus Industrie, Instituten und der Forschung werden die neuesten Entwicklungen aus den Bereichen Beschichten, Drucken und Laminieren vortragen und diverse Versuche in unserem Technikum zeigen.

Zusätzlich bieten wir dieses Jahr einen exclusiven Short Course mit unserem Experten Know-how an.

2025 wird das Symposium zum 24. Mal stattfinden und wir möchten Sie herzlich einladen am 5. und 6. November 2025 an dieser Veranstaltung teilzunehmen.

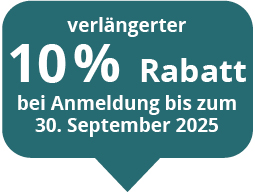

Bitte lassen Sie uns bis zum 24. Oktober 2025 wissen, ob Sie am diesjährigen Symposium teilnehmen möchten und füllen Sie hierzu den Anmeldebogen online aus oder senden Sie eine Mail an Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Agenda folgt

Wir freuen uns auf Sie,

Ihr Coatema Team

Bitte beachten Sie, dass alle Vorträge in englischer Sprache gehalten werden.