The Partnership – Coatema and Heliosonic are planning a partnership

Heliosonic laser induced force transfer

Dormagen/Rüsselsheim am Main, March 6th, 2024

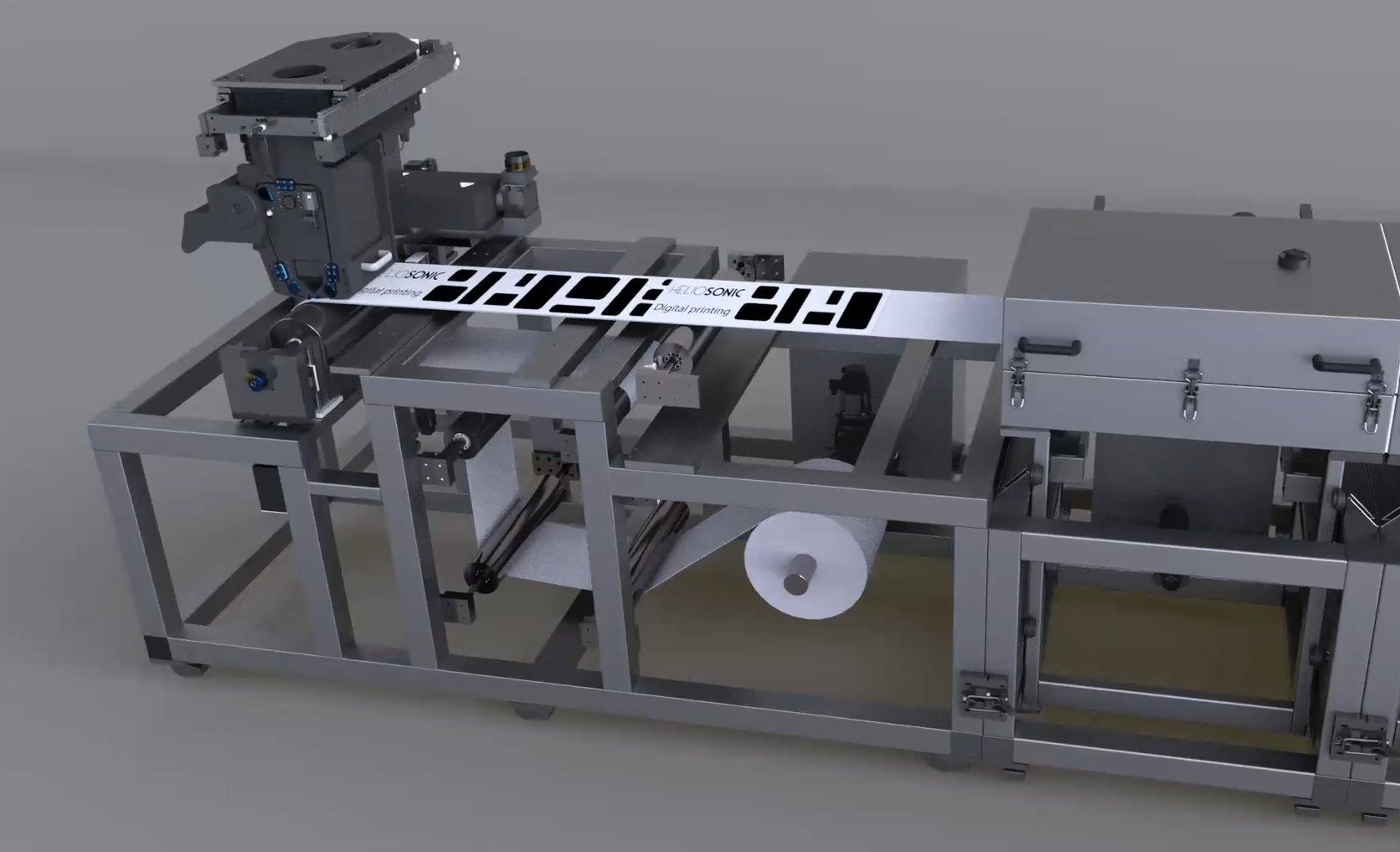

Our joint booth with our Partner HELIOSONIC promises to be the highlight of the event this year. Stay tuned for the launch of fuelcell2print, our high precision digital membrane coating system integrated into a world-class web handling infrastructure. Pre-registration for trial days coming soon!

Key highlights with our partner include a seamless integration of HELIOSONIC print head with Coatema's cutting-edge web handling systems, digital fabrication for renewable energy tech, and a significant leap in printing capabilities, combining speed with unparalleled precision.

The fusion of Coatema's legacy with HELIOSONIC's innovations isn't just a partnership; it's a call to the future of industrial printing. We invite stakeholders, partners, and customers to join us in embracing this new era where potential meets realization.

The Companies

HELIOSONIC – Printing the Unprintable

HELIOSONIC uses and develops a laser-based digital printing technology suitable for material deposition with a large range of inks for several different applications. With this technology, inks that can so far not be printed digitally can be used, such as high viscosity inks or inks containing large particles.

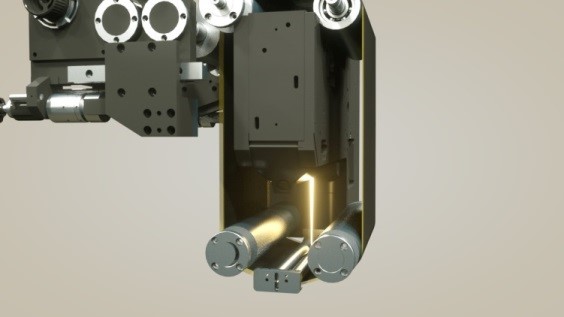

The principle: A carrier belt is coated with a layer of the ink. A laser beam is focused into the ink from the opposite side of the belt. The laser creates a bubble, and, as a result, an ink jet is produced.

While the carrier belt is moving to continuously supply fresh ink to the printing area, the laser beam is scanning over the belt.

Before reaching the scanner unit, the laser beam is passing through an acousto-optical modulator. The acousto-optical modulator can switch the laser on and off, thus creating the digital image.

The acousto-optical modulator is digitally controlled, synchronized with the scanner movement. The patterns for material deposition are given by image files in Tiff-format, that can be designed with any image processing software. The jetting mechanism requires the ink to absorb the laser light (typically approx. 1070nm). For inks that do not absorb at this wavelength, absorbers can be added to the ink.

The benefits

- Fully digital technology

The material deposition is entirely controlled by the print file and the print parameters (such as laser power, for instance). Unlike screen printers, the HELIOSONIC technology does not use a print form. This allows for free form deposition with arbitrary shapes, that can be changed at any time.

- Contactless printing

The print head does not touch the target. Depending on the ink, typical print distances are 200µm to 1mm. Therefore, wet-on-wet deposition is possible. This can be used to increase the thickness of the deposited layer by running multiple prints consecutively on the same target. Also, no pressure is applied to the target.

- Nozzleless printing

In principle, the HELIOSONIC technology can be thought of as an inkjet process without nozzles. Thus, some of the major restrictions of conventional ink jet printers are eliminated. Since no nozzles can be clogged or damaged, high viscosity inks and inks containing large particles can be used.

Heliosonic Print Head

Coatema – From lab2fab

Coatema Coating Machinery GmbH designs and produces Sheet-to-Sheet and Roll-to-Roll equipment for the coating, printing and laminating sectors. For more than 40 years Coatema has designed and built laboratory equipment and pilot/production plants for traditional markets such as the textile sector and the materials converting market.

The laboratory and pilot machinery product lines were expanded more than 20 years ago making Coatema a market leader in emerging technologies such as advanced batteries, solar, prepregs, medical and pharmaceuticals, fuel cells and printed electronics.

To the press release:

https://www.coating-converting.de/news/unternehmen-maerkte/Unternehmen-Coatema-und-Heliosonic-planen-Partnerschaft-29932

https://proconverting.com/flextronics/coatema-and-heliosonic/

https://ope-journal.com/news/coatema-and-heliosonic-announce-partnership

https://www.techblick.com/post/coatema-and-helisonic-laser-induced-force-transfer-technology

Marketing Contakt:

Tanja Simone, Marketing Manager

Telefon: +49 (0) 21 33 / 97 84 – 121

This email address is being protected from spambots. You need JavaScript enabled to view it. | www.coatema.com